Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

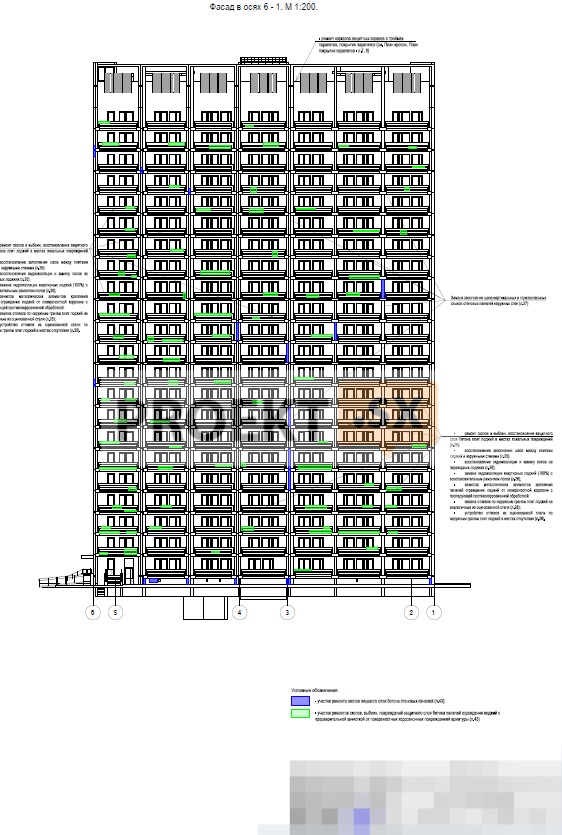

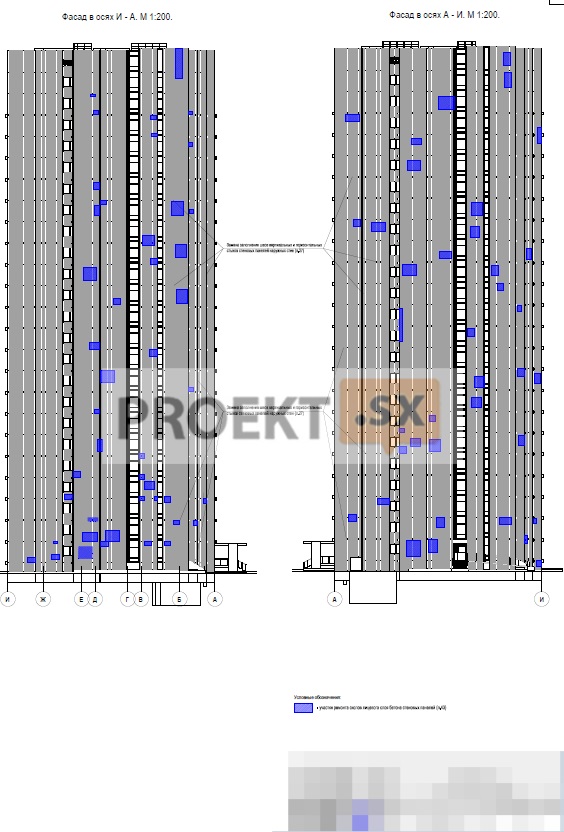

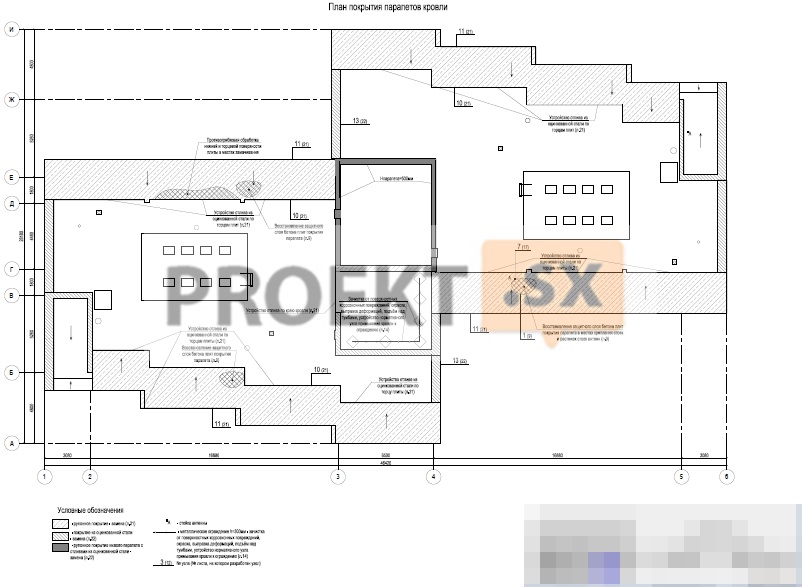

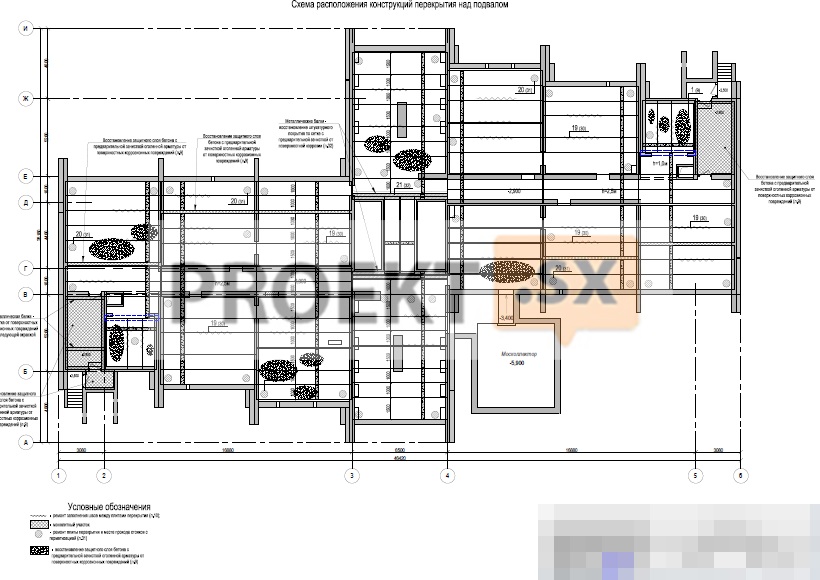

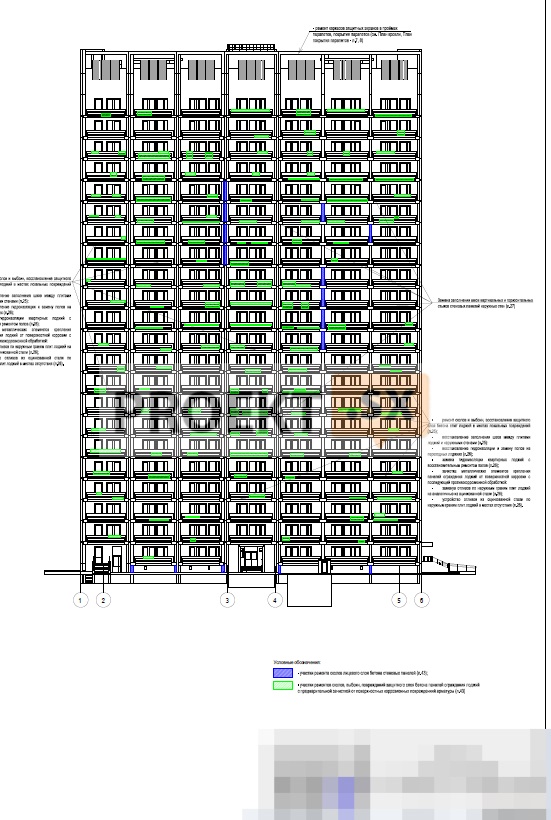

Typical project I-700A

Project documentation including estimates for the overhaul of an apartment building series I-700A

Technical and economic indicators

Year Built: 1981

Building configuration in plan: complex shape in plan with overall dimensions in plan:

Number of floors of the object: 22 floors

Height: constant, from ground level to the highest point in the region of 75 m.

Structural scheme of the building: a multi-storey frameless building with load-bearing external and internal large-block walls.

Area (usable living area): 5724 m2

Area (total): 10912 m2

Number of apartments: 171 apartments

Area (non-residential premises): 268 m2

Construction volume: 52 m446

Building area: 900,4 m2

Purpose of the building: Multi-apartment residential building.

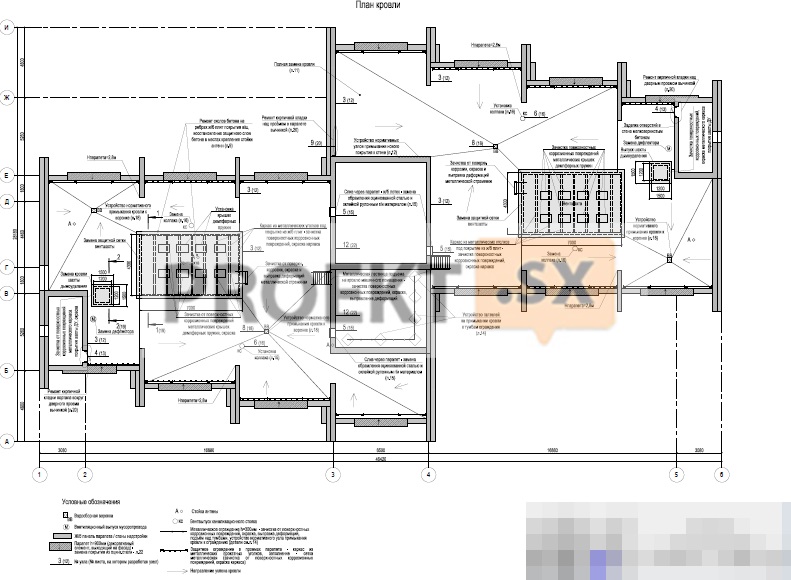

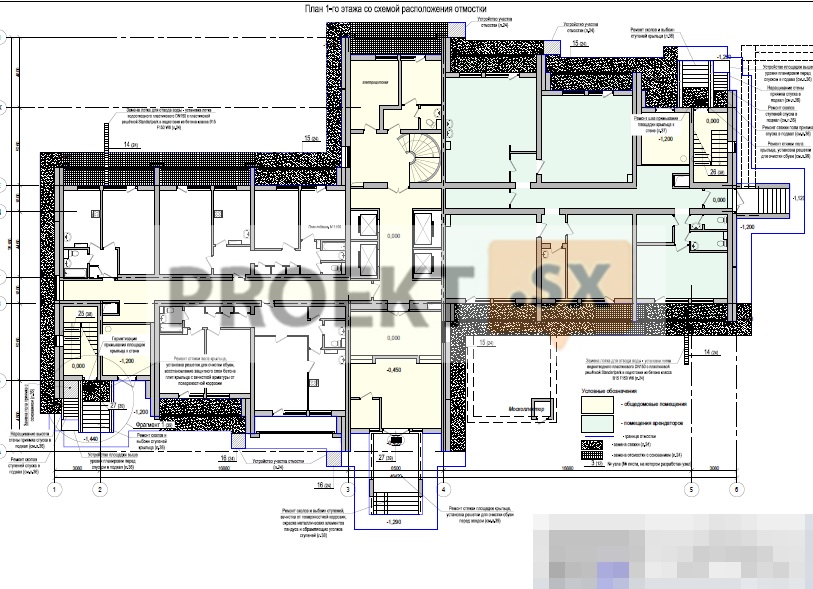

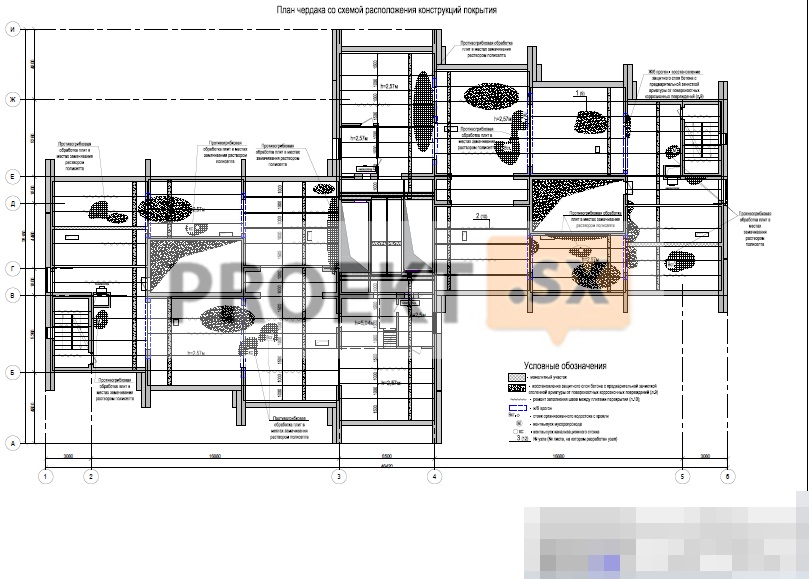

Number of floors: 22 floors. There is a basement under the whole building and a technical attic.

Year of construction, superstructure and last overhaul: 1981 built.

Building series/modification: Series I-700A.

Number of sections: 2 sections, 2 entrances.

General information.

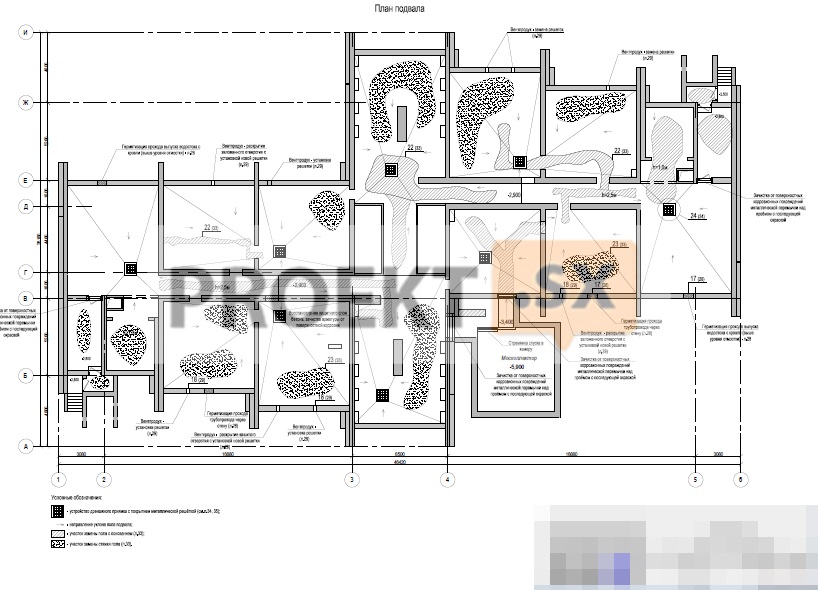

The building was built in 1981 according to the standard project of the I-700A series. The building is 22-storey, 2-entrance for 171 apartments, with a total area of 10912 sq.m., a technical floor in the attic level and a technical basement under the entire building. The internal walls of the building were built from prefabricated reinforced concrete blocks 320 and 390 mm thick per floor. The outer walls along axes 1, 3, 4, 6 are two-layer: the inner bearing part is made of prefabricated reinforced concrete blocks 320 mm thick per floor, the outer one is made of prefabricated three-layer (concrete-insulation-concrete) hinged reinforced concrete panels 300 mm thick with embossed outer surface. The outer walls along the facades in axes 1-6 and 6-1 are made of prefabricated three-layer (concrete - insulation - concrete) reinforced concrete panels 300 mm thick with a relief outer surface. The foundations of the outer and inner walls of the building are tape pile with a monolithic reinforced concrete grillage. The attic and interfloor floors are made of prefabricated multi-hollow reinforced concrete slabs of the PK type with a thickness of 220 mm and a width of 1,0 and 1,5 m, based on external and internal walls made of reinforced concrete blocks and panels and internal prefabricated reinforced concrete girders. The pavement is made of prefabricated multi-hollow reinforced concrete slabs of the PK type with a thickness of 220 mm and a width of 1,0 and 1,5 m and reinforced concrete monolithic sections based on external and internal walls made of reinforced concrete blocks and panels and internal prefabricated reinforced concrete girders. There are no jumpers. The openings are made in reinforced concrete blocks one floor high. The walls of the basement are made of prefabricated reinforced concrete blocks 320 and 390 mm thick per floor with local seals made of solid ceramic bricks on a c / p mortar and concrete blocks of the FBS type. On the top of the blocks (under the ceiling) a number of reinforced concrete crossbars are laid. The walls are painted. Above the individual openings of the basement, lintels are made of rolled metal profiles. Most of the ceiling above the basement is made of prefabricated multi-hollow reinforced concrete slabs of the PK type, 220 mm thick, 1,0 and 1,5 m wide, and reinforced concrete monolithic sections, based on external and internal walls made of reinforced concrete blocks and internal prefabricated reinforced concrete girders. Within the limits of the elevator unit along the D and D axes, two beams are made of rolled metal profiles to support the plates between the elevator shafts. In the axes 1-2/B-C and 5-6/E-F, the floors are monolithic reinforced concrete along the load-bearing walls and metal beams. The basement floors are made on the ground. The floor covering is a cement-sand mortar screed 50 mm thick on a concrete base 50 ... 100 mm thick. Entrances to the basement are provided from two pits: in axes 1-2/А-Б and 5-6/Ж-И. The pits are limited by the outer walls of the building and retaining walls made of ceramic solid bricks on a c / n mortar 380 mm thick on one side and 510 mm thick on the other (the 510 mm thick wall is also the wall of the entrance porch to the smoke-free stairwell). The walls of the pits are plastered and painted. The descent ladder to the pit is made of prefabricated reinforced concrete steps resting on the walls of the pit. The floors of the pits are made on the ground.