Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

The project of a sports and recreation complex

Technical and economic indicators:

Land allotment area m2: 13881

Improvement area m2: 11340

Building area m2: 2534,7

Building density %: 22,4

Hard surface area m2: 3405,6

Landscaping area m2: 5399,7

Architectural and space-planning solutions

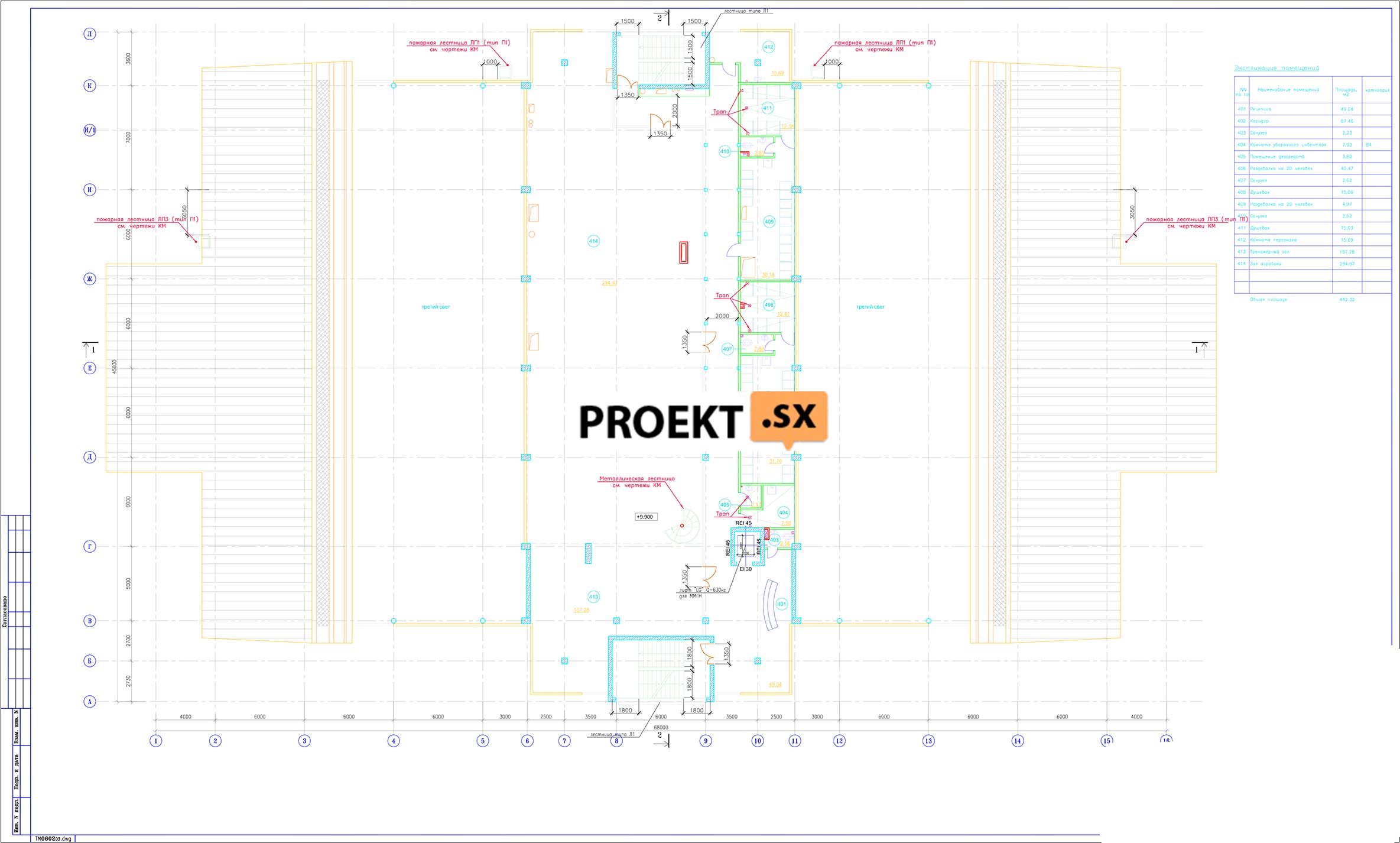

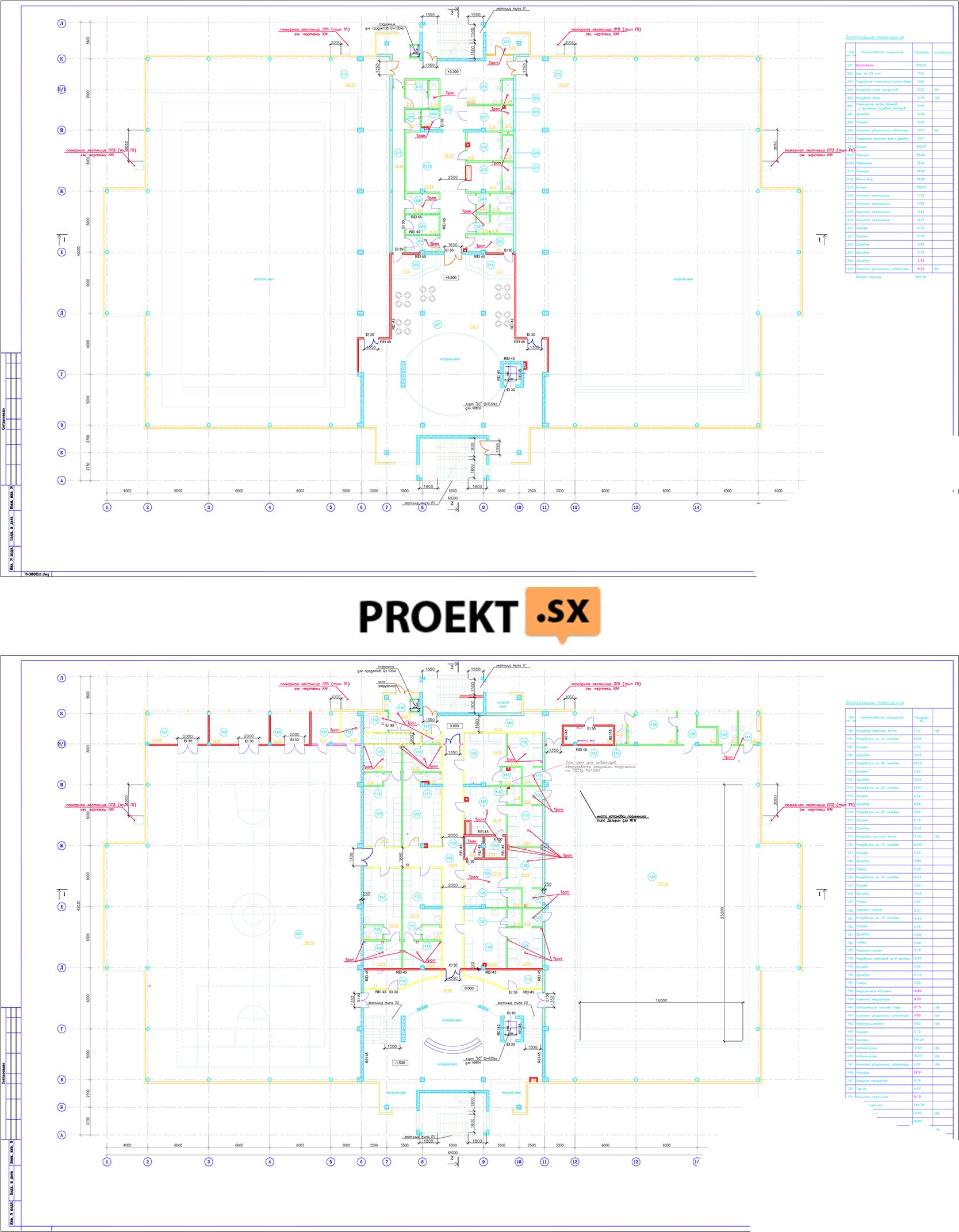

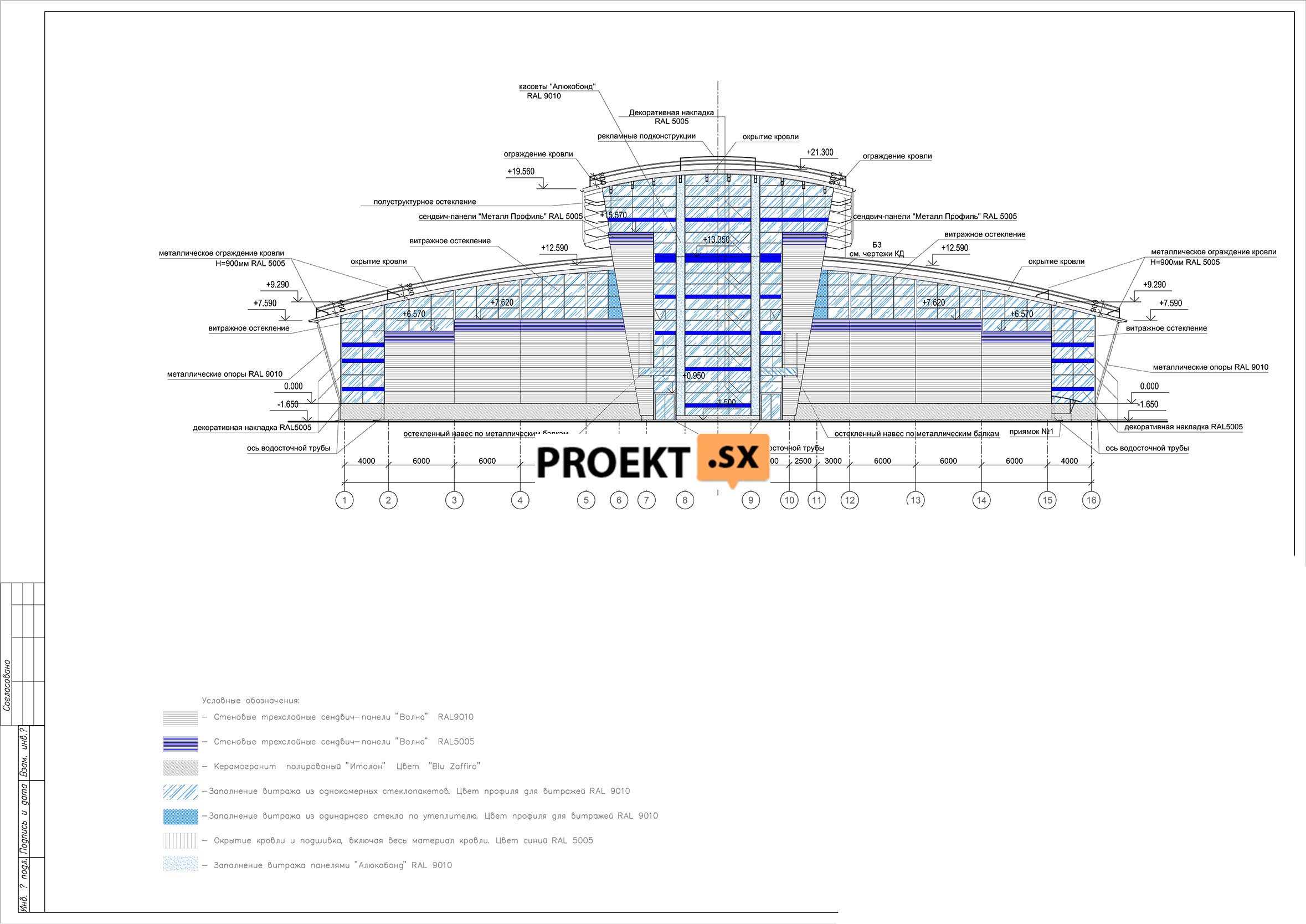

The project documentation for the site provides for the construction of an indoor sports complex without stands for spectators. The building is complex in plan, with dimensions in the extreme axes of 68,00 x 45,03 m. The building is intended to accommodate a sports complex. It has been designed: a swimming pool, a sports hall, an aerobics hall and a gym, technical and utility rooms. The building consists of three main parts and has a symmetrical composition. The central part of the building is designed as a 5-storey building with a complex curved roof. External walls at the level of 4-5 floors are designed with a reverse slope of 10%. The maximum height from the planning mark of the ground to the highest point of the roof is 22,85 m. Glazed staircases are designed along the longitudinal axis of the central part. On both sides of the central part, adjacent three-height volumes of a sports hall and a swimming pool with utility rooms are designed. The height of the three-light volumes from the planning mark of the earth to the highest point is 14,24 m. The roof is pitched along the general radius. The entrance vestibule is designed at elevations of -1,500 and 0,000 with a second light. Open staircases are designed in the lobby, connecting it with the basement floor. In the basement at around -3,300 are designed: a wardrobe, sanitary facilities, utility rooms, storerooms, technical rooms of the pool, a ventilation chamber and a heating center. On the ground floor, at a relative elevation of 0,000, a swimming pool with a bowl of 25,2x16 m with bypass paths, a gym, inventory rooms, dressing rooms with showers, bathrooms and “Turkish” steam rooms, a medical office, administrative premises, a loading bar and utility rooms are designed. On the second floor, at +3,300 relative elevation, two bars, VIP dressing rooms, sanitary facilities and utility rooms are designed. On the third floor, at +6,600 relative elevation, the premises of the administration of the complex, meeting rooms, server room, control room, sound control room, sanitary facilities and ventilation chambers are designed. On the fourth floor at +9,900 there is an aerobics room, a gym, dressing rooms with showers and sanitary facilities, a staff room and utility rooms. On the fifth floor at +13,650, a sports hall, a ventilation chamber and an open gallery are designed. For vertical communication between floors, an elevator with a carrying capacity of 630 kg with cabin dimensions of 1100x1400 and two staircases of the L1 type is provided. External walls - three-layer "sandwich" panels and stained glass windows. The ground floor is reinforced concrete, lined with polished ceramic granite. Glazed canopies on metal brackets are designed above the main entrance. The roof is rolled with an organized drain. Partitions - made of reinforced concrete, aerated concrete, post-ridge slabs, framed sheathing with plasterboard slabs. In technical rooms and rooms with a wet regime - solid brick, 120 mm thick, plastered on both sides. The project documentation ensures the accessibility of the complex for people with limited mobility. At a relative mark of 0,000, there is a wardrobe for MGN, a locker room for the disabled for 3 people, and universal sanitary facilities. A container gas stand-alone boiler house is designed on the site, operating without maintenance personnel. The building is one-storey with dimensions in the axes of 9,0 x 6,54 m.

Structural and space-planning solutions

The level of responsibility of the building of the complex is II. The building of the complex is designed in the form of three blocks - the central five-story block and one-story blocks (gym and swimming pool). Blocks are designed in various constructive schemes. The construction scheme of the gym and swimming pool is a one-storey frame covered with bent-laminated wooden beams hinged on reinforced concrete and steel columns. Curvilinear beams, one- and two-span, beam spacing from 5,0 to 7,0 m. Beam span 21,0 m and 21,0 + 4,0 m. Beam width - 220 mm, height - from 832 to 1660 mm. Steel columns - from electric-welded pipes with a diameter of 325 mm with a monolithic reinforced concrete core. Spatial rigidity of the frame is provided by vertical connections between steel columns, horizontal wooden and steel connections in the plane of the coating. The structural scheme of the central block is a spatial frame of monolithic reinforced concrete structures, rigidly interconnected columns, floor slabs, walls (longitudinal, transverse) and stairwells. Grid of columns - 6,0 x 6,0 m. Columns - section 400x400 mm; 600x400 mm. Ceilings - beamless slabs 240 mm thick supported on columns through hidden cantilevers from channels. Walls - 250 thick; 300 mm. The material of monolithic structures is concrete of class B25, F100, W6, class AIII reinforcement. The block cover has a complex curvilinear shape. The load-bearing structures of the coating are single-span bent-laminated wooden beams with cantilevers, hinged on columns and located at various elevations. Span of beams - 18,0 m; removal of consoles - 3,15 m; section of beams -220x1350 (h) mm. Glued wooden structures will be treated with antiseptic bioprotective compounds. A profiled flooring with a polymer coating is attached to the wooden load-bearing structures of the coating. External walls of the complex: sandwich panels; facade cassettes and stained-glass windows are attached to steel half-timbered structures. The pool bowl with dimensions of 25x16 m is designed in monolithic reinforced concrete (B30; W8; F75). Wall thickness - 300 mm. The bottom of the pool is a beamless slab 300 mm thick, supported by columns with a section of 400x400 mm. Waterproofing from polymeric materials is carried out according to the technology of a specialized organization. Stairs are designed from monolithic reinforced concrete, B25 concrete. The elevator shafts are designed from monolithic reinforced concrete. Wall thickness 250 mm. Concrete B25, reinforcement AIII. The spatial rigidity and stability of the building is ensured by the joint work of the longitudinal and transverse load-bearing walls, the walls of the stairwells, the rigidity of the supporting nodes of the columns and the hard disks of the floors. The calculation of load-bearing structures was carried out on a computer using the SCAD Office program (version 11.1). Calculation and design documentation of wooden glued structures have been completed, a conclusion has been received for the project of wooden glued structures. The foundations are assumed to be piled. Piles - driven with a section of 350x350 mm, 9 and 11 m long. Concrete piles B25,W6, F100. Efforts in piles no more than 60t. Grillages - columnar and tape made of monolithic reinforced concrete, concrete class B25, W6, F75. Column grillages - 800 mm high and strip grillages - 600 mm high, united by a 200 mm thick plate. Pairing of piles and grillage is rigid. Under the grillages and the floor slab, a concrete preparation 100 mm thick is provided along a sand cushion 300 and 1200 mm thick. The relative elevation of 0.000 corresponds to the absolute elevation of +11.170 m. According to the report on engineering and geological surveys of IGL GeoProject LLC (reg. No. 0921/1) of 2010, the base of the piles are dusty gray dense sands with e = 0,55, E = 240 kg/cm2. The allowable design load on the pile is 60 tons, based on the results of static sounding. Before mass piling, the bearing capacity will be checked by static tests. After the installation of the pile field, control tests of the piles will be carried out. In order to protect the concrete of underground structures, the concrete grade for water resistance is W6, the concrete surface is protected by coating with a primer twice. The project provides for the internal waterproofing of the basement by applying Aquafin cement-polymer mastic to the surface. The expected average settlement of the building is not more than ~2,0 cm. Boiler room: The modular boiler room is designed from easily assembled metal structures with sandwich panel cladding. Metal structures are designed from a closed bent profile 140x100x6, etc. (connections from a bent profile 80x4) in accordance with GOST 30245-2003. External walls - hinged "sandwich" panels 100 mm thick. Covering - from "sandwich" panels 100 mm thick on a metal frame. The spatial rigidity and stability of the building is ensured by vertical connections and rigid junctions of columns and crossbars. The foundation is taken in the form of a monolithic reinforced concrete slab 250 mm thick, concrete B20, W6, F50. Under the foundation, crushed stone preparation 100 mm thick is provided with pouring with bitumen until full saturation. Chimneys (gas ducts) with a height of 9 m and an outer diameter of 450 and 550 mm are fixed on the spatial metal structure of the exhaust tower, installed on its own foundation. The metal structures of the exhaust tower of the chimneys are made of racks (a pipe with a diameter of 89x5) united by a grid of 70x6 corners. The foundations for the exhaust tower are columnar on a natural foundation. Concrete B20,W6, F50. The relative elevation of 0.00 corresponds to the absolute elevation of +9,57 m. According to the report on engineering and geological surveys of IGL GeoProject LLC (reg. No. 0921/1) of 2010, silty plastic sandy loams with Е=104 kg/cm2, φ=24о serve as foundation foundations. The design resistance of the base soil is not lower than R = 1.8 kg/cm2, the pressure on the base soil is not more than 0,19 kg/cm2. In order to protect the concrete of underground structures, the concrete grade for water resistance is W6, the concrete surface is protected by coating with mastic twice. The expected average settlement of the building is less than the maximum allowable.