Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

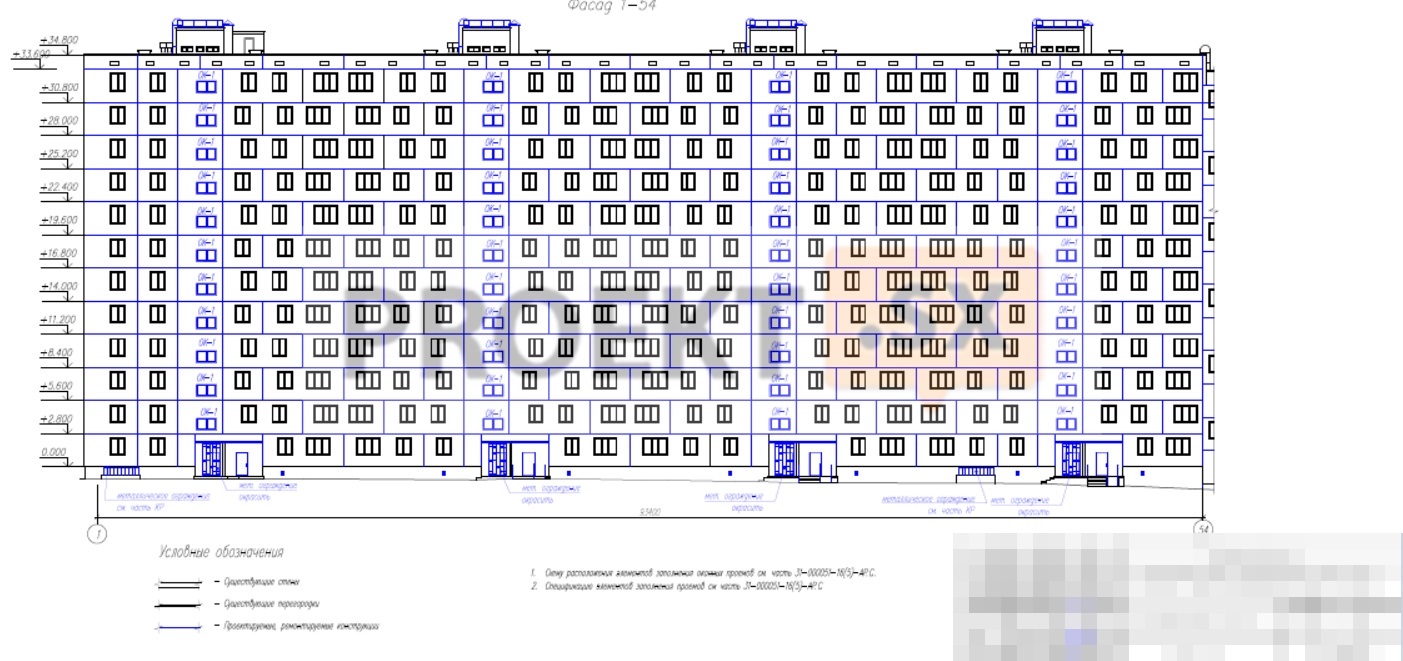

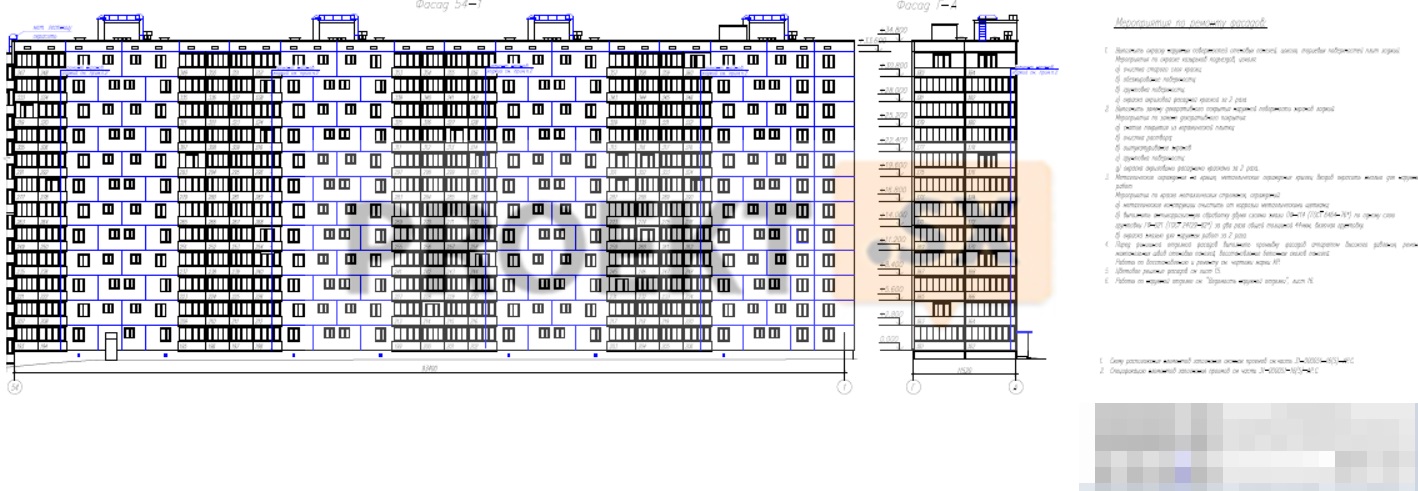

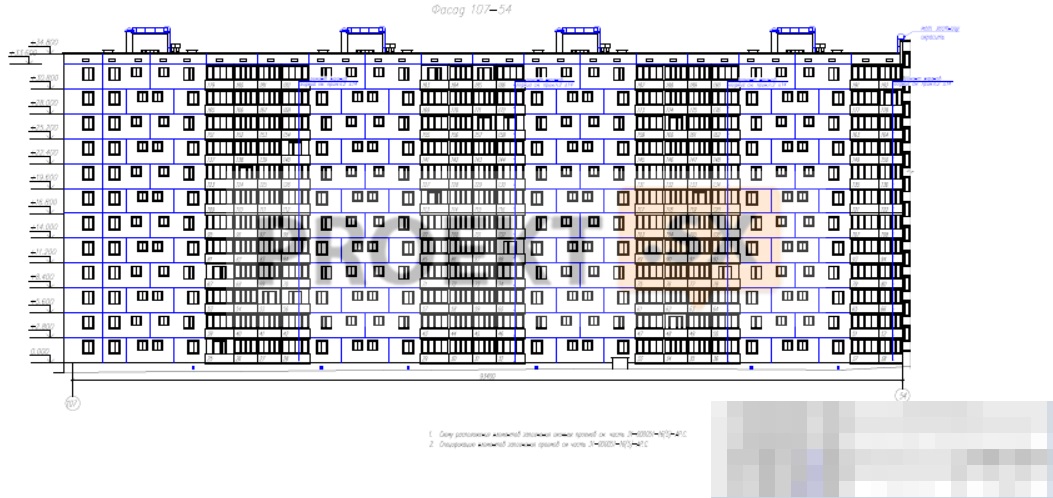

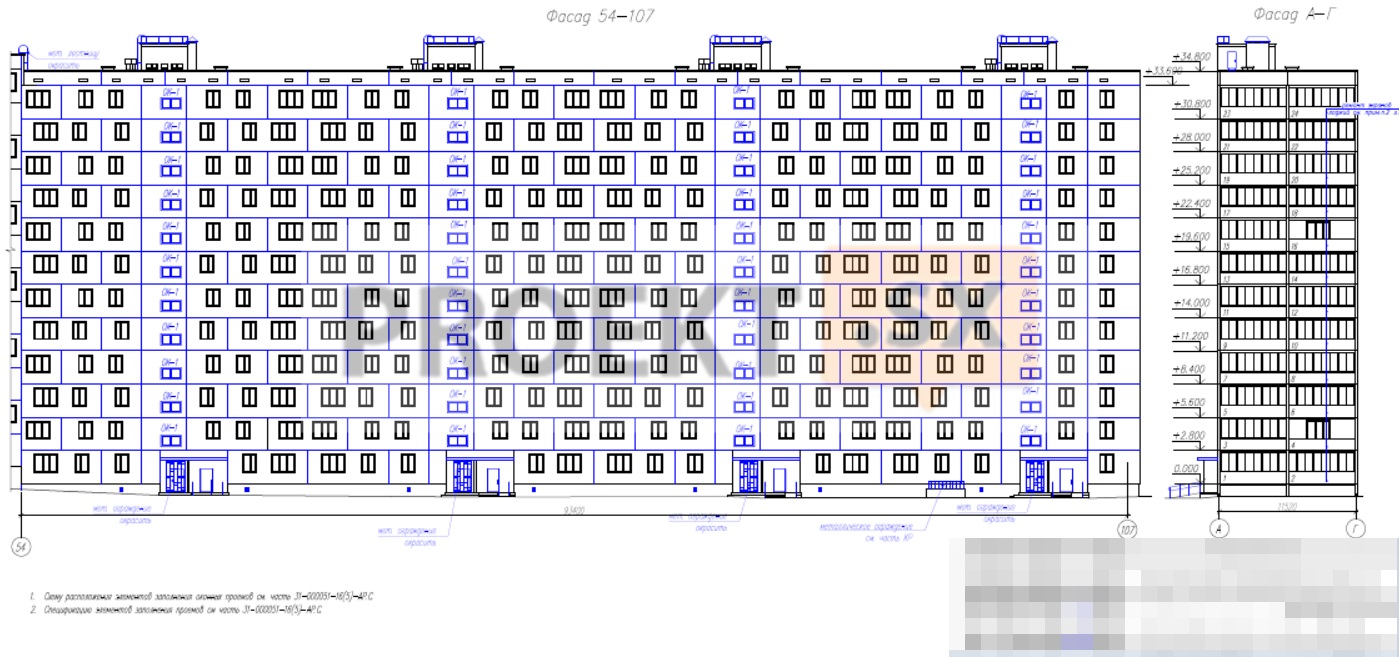

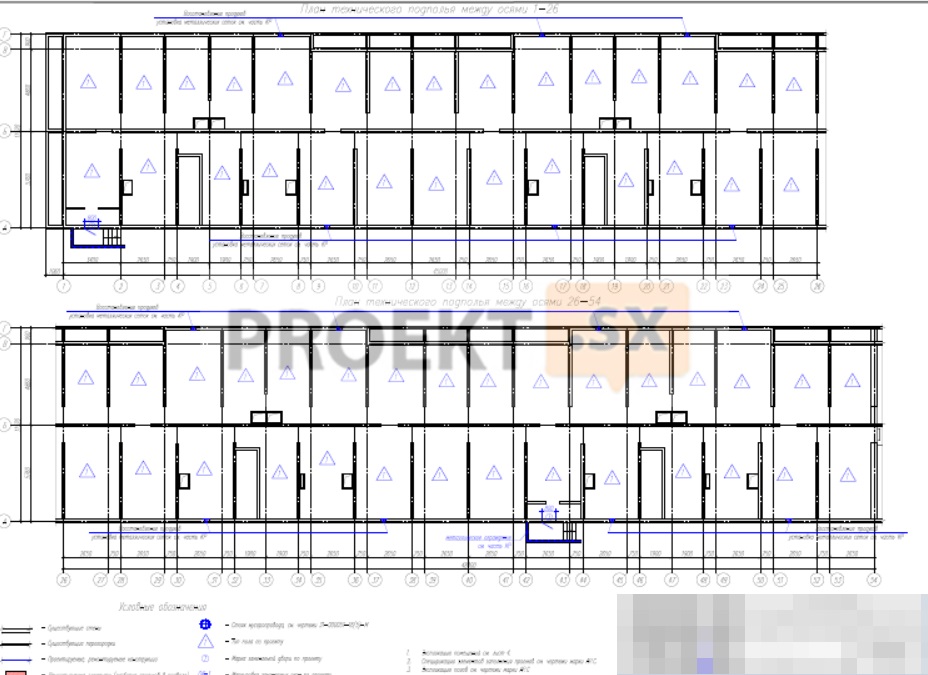

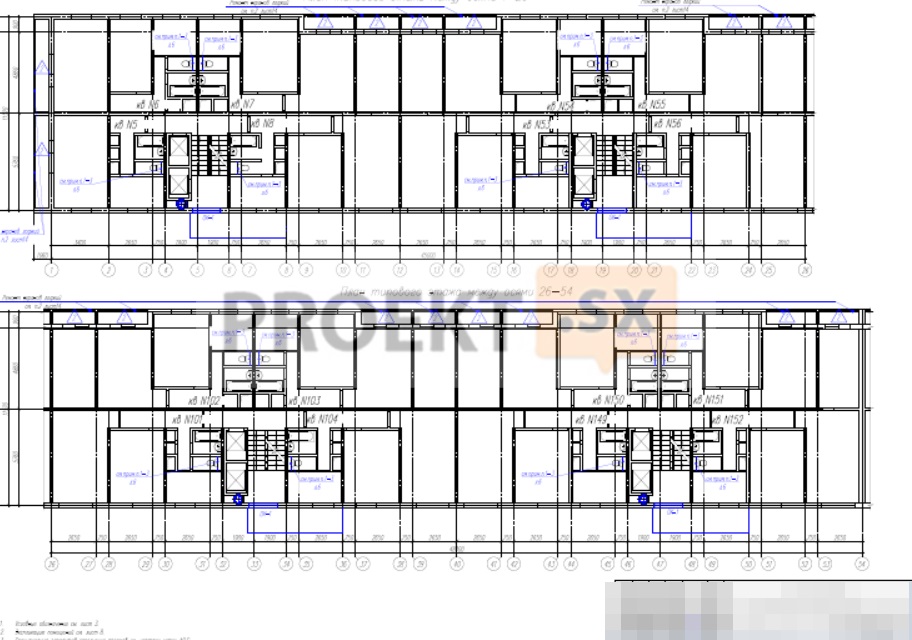

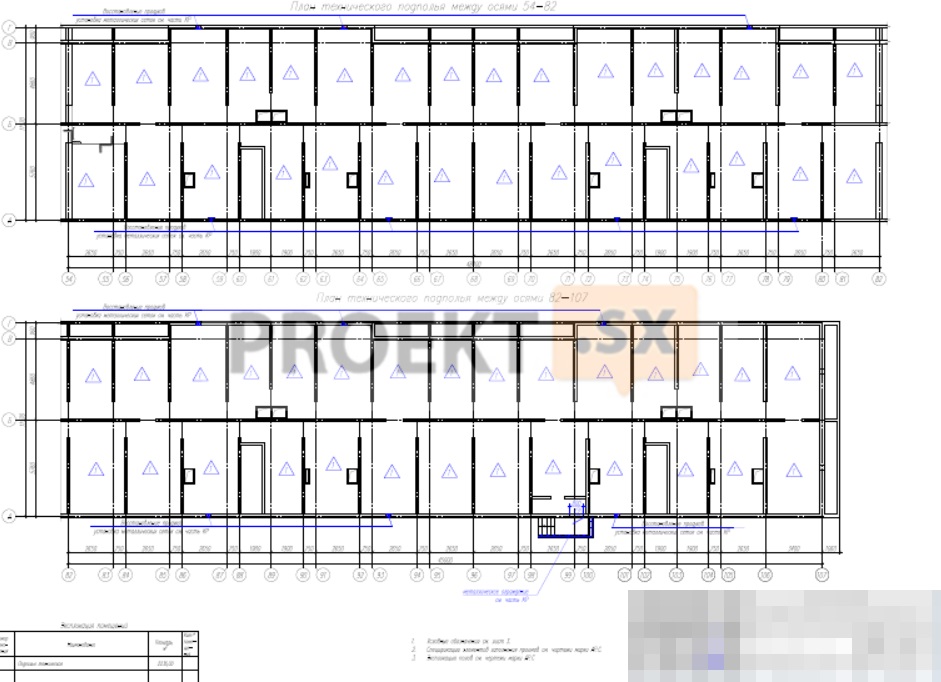

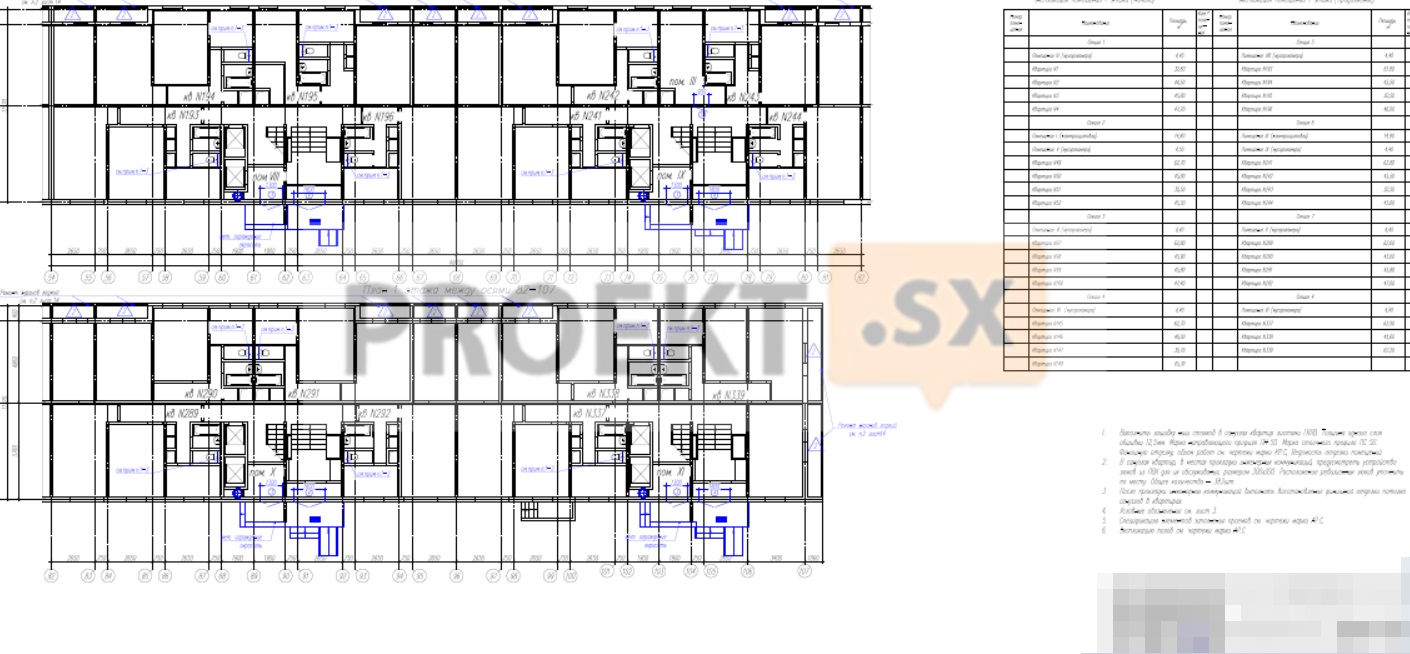

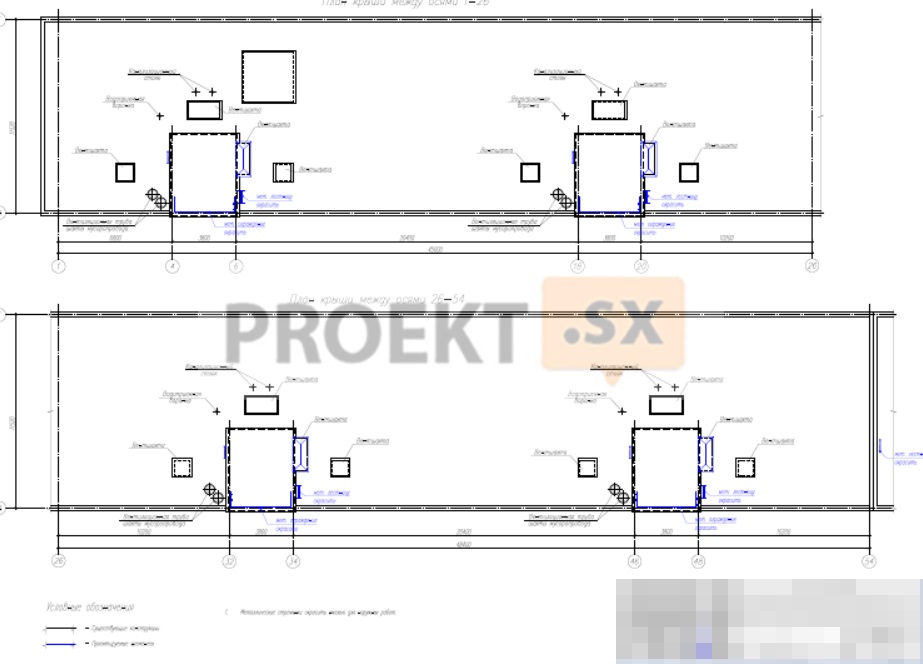

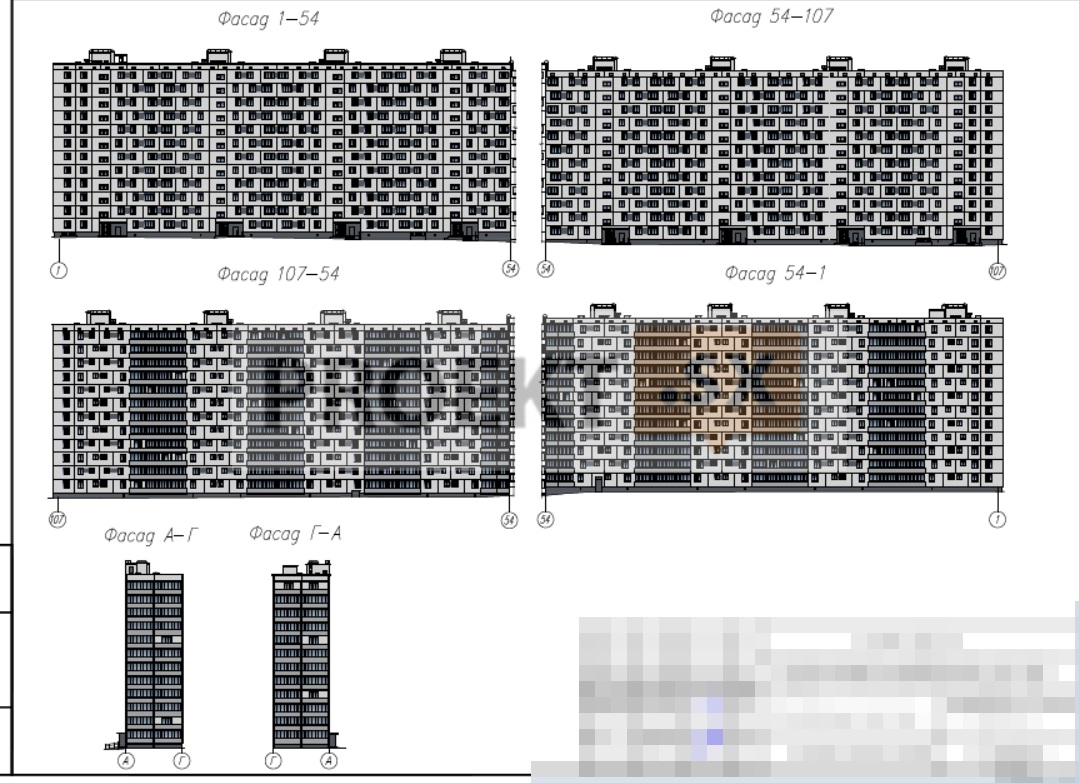

Standard project 1605-AM

Working documentation including estimates for the overhaul of an apartment building series 1605-AM

Technical and economic indicators

Year Built: 1973

Floors: 12+basement

Building area: 2343,6 m2

Building volume: 82578 m3

Total building area: 20474,1 m2

Total area of apartments: 19873,1 m2

Living area of apartments: 13559,6 m2

Total number of apartments: 383

Including:

three-room apartments: 162

two-room apartments: 194

one-room apartments: 27

Number of sections: 8

General information.

Foundations - tape from prefabricated reinforced concrete blocks. The outer walls of the basement are made of prefabricated reinforced concrete plinth panels 200mm and 250mm thick (end walls). The outer walls of the 1st - 12th floors are made of expanded clay concrete panels 250mm and 300mm thick (in the entrance groups). Internal longitudinal and transverse load-bearing walls are made of prefabricated reinforced concrete panels 160mm thick. The outer surfaces of the outer wall panels have a painted textured layer of decorative concrete. The plinth panels are lined with ceramic tiles and painted. Overlapping, covering - from prefabricated reinforced concrete slabs with a size of "per room" and "half a room" with a thickness of 140mm. The slabs are supported on internal and external load-bearing walls. The covering is made of reinforced concrete roofing slabs with an air gap for ventilation. The slabs are supported on internal and external load-bearing walls. Stairs are internal two-flight, made of prefabricated reinforced concrete marches and prefabricated reinforced concrete ribbed platforms. The steps are smooth concrete. Fencing - from a metal lattice 900 mm high with a plastic handrail. The roof is flat, non-attic, combined, with a ventilated gap, rolled, with an internal drain. Rolled carpet is made of 2 layers of rolled deposited material. Parapet height 600mm, with apron made of galvanized steel roofing. Metal fencing along the front of the roof superstructures (roof exits and machine rooms). Ventilation shafts are prefabricated reinforced concrete. The covering of ventilation shafts is made of prefabricated reinforced concrete slabs and umbrellas made of galvanized roofing steel. Access to the roof is via a metal ladder from the level of the 12th floor leading to the vestibule on the roof superstructure, from which, in turn, there is access to the elevator machine room and access to the roof. Drainage is internal organized. The windows of the apartments of the residential building are wooden, double in paired bindings, made of PVC profiles with double-glazed windows, metal ebbs. The windows of the stairwells are wooden, single with double glazing with metal tints. External doors of entrances - metal, deaf. The internal doors of the apartments are metal entrance doors, wooden panel and panel doors. Loggias are located on three sides of the building, made of prefabricated reinforced concrete slabs 140mm thick. Support is carried out on external and internal load-bearing walls. The fence of the loggias is made of reinforced concrete panels lined with ceramic tiles. Most of the loggias are glazed. The entrance porches to the entrances are made of reinforced concrete slabs lined with ceramic tiles. Above all the entrances to the entrances there are canopies made of reinforced concrete slabs 200 mm thick, resting on the outer walls and a support made of a reinforced concrete transverse wall in the middle of the canopy. Covering of a peak from the soft built-up rolled materials. Entrances to the basement are located from the courtyard facade of the building. The walls of the descents to the basement are made of prefabricated reinforced concrete panels, 150 mm thick. The steps of the entrances are prefabricated reinforced concrete. The blind area is asphalt along the perimeter of the building. Garbage chute - built-in, closed, located in the stairwell between the elevator shaft and the outer wall. The trunk of the garbage chute is made of asbestos-cement pipes with a diameter of 400 mm. The central heating system of the building is independent, connection to the heating network through the central heating system. The heating system is single-pipe with bottom wiring of the supply and return lines. Temperature chart 95-70°C. Pipelines run through the basement above the floor. The risers of the system are laid, hidden, without sleeves. Steel convectors are installed as heating devices. Connection to the heating network is independent. The supply and return lines are made of black pipes with a diameter of 12520 mm. The risers are made of black pipes with a diameter of 20 laid hidden. Entering 2tr Du150 is carried out by steel pipes along the facade of the building in the sixth entrance. Entering in the opening of the outer wall. The building has a combined system of fire-fighting water supply, with a lower line wiring. Fire risers d = 50MM, located on the staircase, are ringed on the 12th floor. The water supply of the building is carried out from two inputs D=100mm, located in the pit near the outer wall of the technical basement. A water meter unit with a bypass line and a BMX-65 water meter is installed at the inlet. In the garbage chamber room, cold water is supplied to the watering tap. The main pipeline after the water meter assembly of galvanized steel and partially black pipes D = 100-32 mm is laid under the basement ceiling. Risers and connections in the bathrooms on the floors of galvanized steel pipes D = 32-15 mm are laid in the sanitary ware. cabinets. The building has a hot water supply system with a lower distribution of supply lines and a circulation line. The water supply of the building is carried out from the inputs D=100,80 mm, located in the pit near the outer wall of the basement. Gate valves are installed at the input. A metering unit for hot and circulating water is installed at the inlet. The supply distributing pipeline made of galvanized steel and partially black pipes D = 100-32 mm is laid under the basement ceiling; the circulation distributing pipeline made of galvanized steel and partially black pipes D = 80-32 mm is laid under the basement ceiling. Risers and plumbing in the bathrooms on the floors of galvanized steel pipes D = 32-15 mm from galvanized steel pipes are laid in the sanitary tech. cabinets and looped under the ceiling of the 12th floor. Heated towel rails D=32, 25 mm are made of galvanized and stainless steel pipes and are connected to supply and circulation risers. Hot water is supplied to the waste chamber from the circulation pipeline. The building has an internal sewerage system made of cast-iron socket sewer pipes D = 150, 100, 50 mm. There is a ladder in the premises of the waste chambers. Main pipelines made of cast-iron pipes, with partial replacement for HDPE pipes with outlets from each section to the yard network, are laid openly and partially hidden in the basement floor. Risers D = 100 mm are laid in the sanitary tech. cabinets, risers in the technical underground are laid open. Discharge pipes from sanitary fixtures made of cast-iron pipes are laid openly above the floor of bathrooms and kitchens. All riser hoods made of cast-iron pipes D = 100 mm are removed by the exhaust part above the roof level. The building has an internal rain sewerage system made of steel electric-welded pipes D = 100 mm. Main pipelines made of steel electric-welded pipes with outlets to the blind area from each section 1 outlet to the blind area. On the roof, drain funnels with a leaf catcher are installed. Risers D = 100 mm are laid in the sanitary tech. cabinets, risers in the technical underground are laid open. The building has a natural ventilation system. The air flow is carried out through the vents and leaks in the window and door porches. Exhaust vertical channels are mounted in the structure of the internal walls in the bathroom. nodes and kitchens. In the kitchens and bathrooms, metal and plastic louvered ventilation grilles sized 150x200 are installed. Deflectors are mounted above the garbage chute shafts. Smoke protection system In order to protect escape routes from smoke during a fire, a smoke protection system is provided. The installation of a smoke exhaust valve at the top of the staircase is provided. The exhaust shaft is concrete, located above the roof level. A black steel umbrella is installed above the smoke protection shaft. The location of the electrical panel room is on the 1st floor 2 entrances (VRU1) and 6 entrances (VRU2). Mains voltage-380/220V. Input 1 VRU1-ASB 3x185 beam A from TP14937. Input 2 VRU1-ASB 3x185 beam B from TP14937. Input 1 VRU2-ASB 3x185 beam A from TP14937. Input 2 ASU2-2ASB 3x95 beam B from TP14937. VRU1 and VRU2 without type marking (3 panels) size 1750x400x2000mm (WxDxH) - 2 sections. Floor guards of non-standard execution. There are no group shields. The supply lines from the ASP to the main risers are open in the basement in metal pipes with copper wire, on the floors in the existing embedded channels. The main risers are hidden. Group lighting networks of common premises - hidden, open in pipes. The lighting network of apartments is hidden. Lighting of staircases, halls, vestibules and entrances of the building is hidden by aluminum wire under a layer of plaster.