Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

Swimming pool project

Plot area, ha: 1,296

Building area, m2: 3445.0

Total area, m2: 8245,5

Building volume, including, m3: 46629.7

below el. 0.000, m3: 10675.0

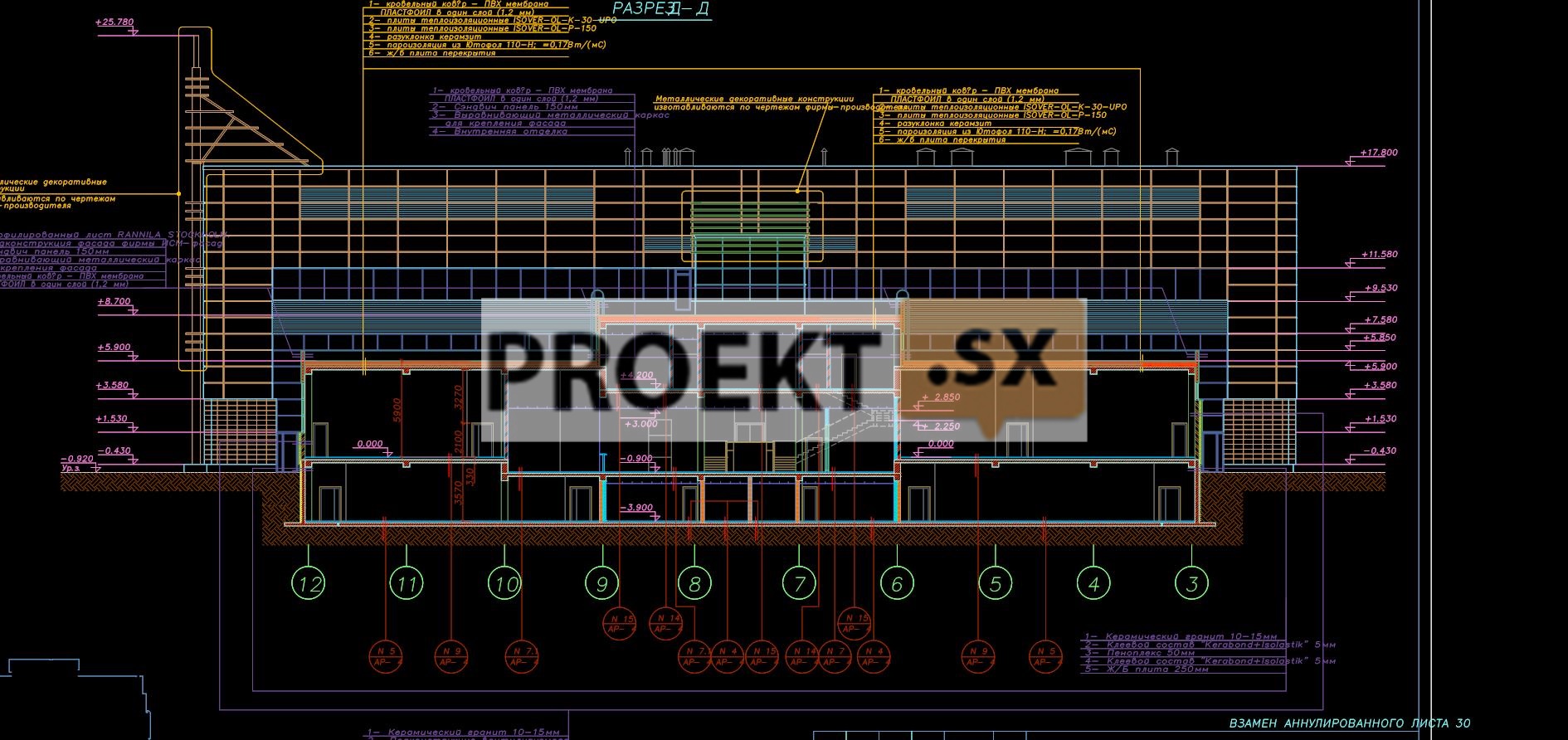

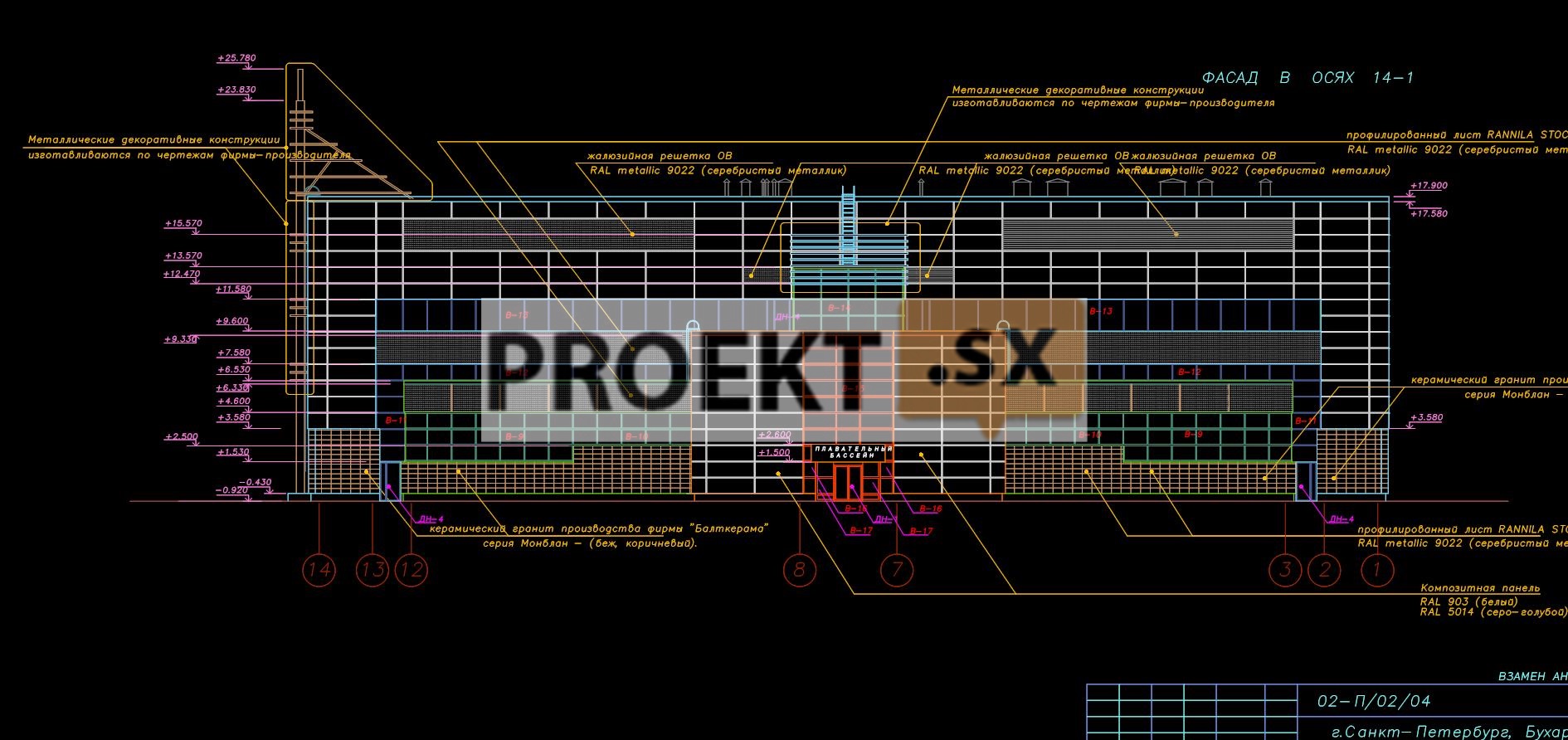

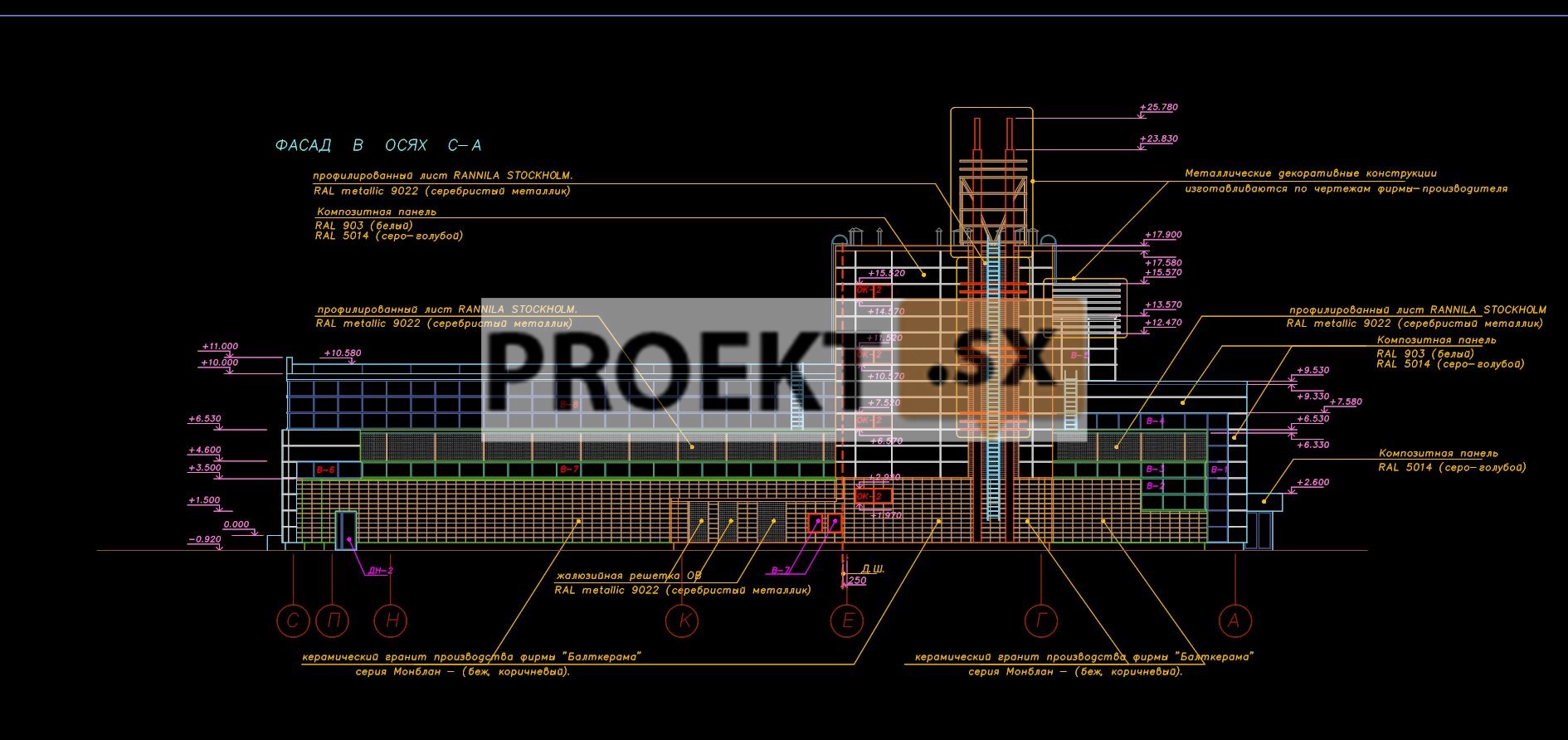

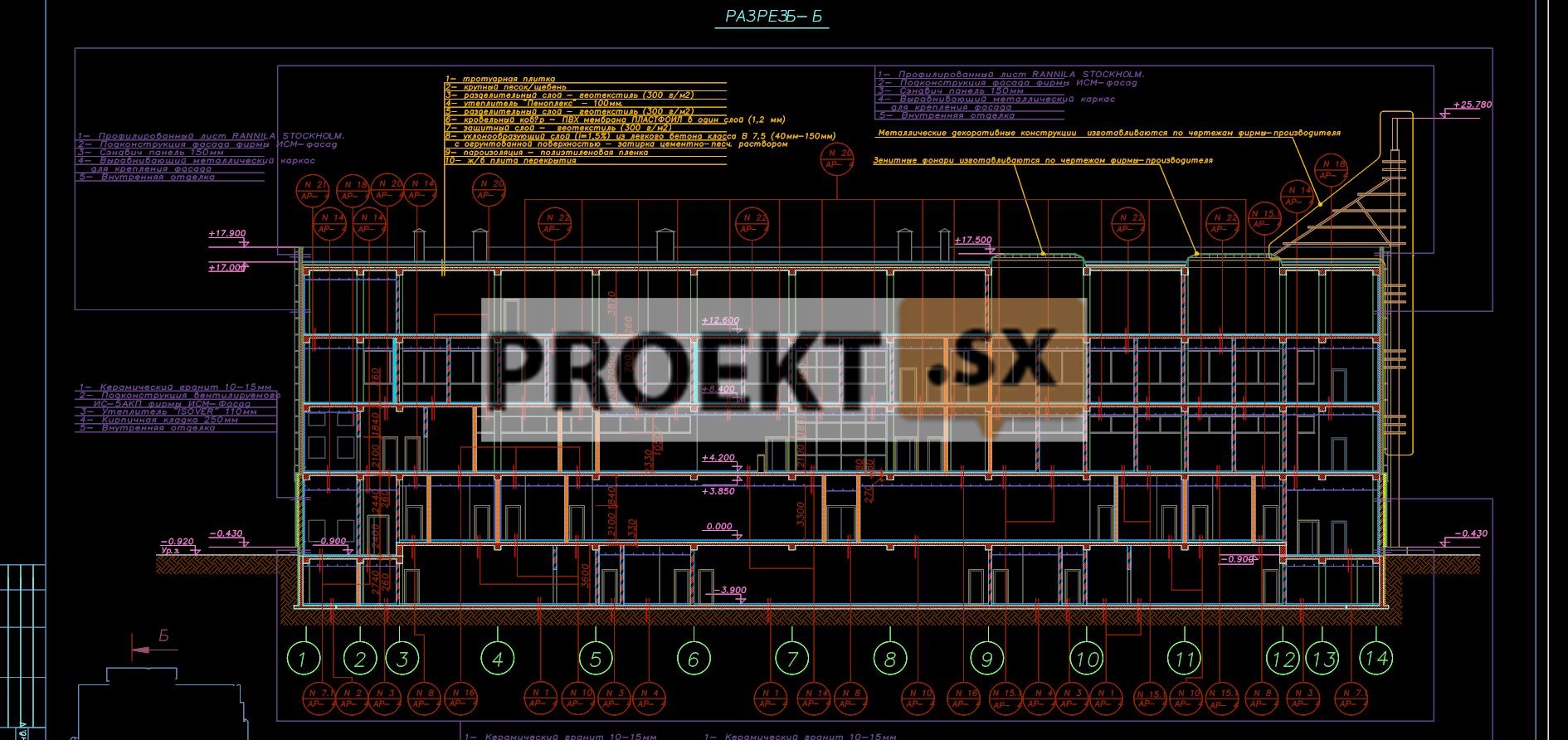

Floors, fl.: 1-2-3-4 with basement

Architectural and space-planning solutions.

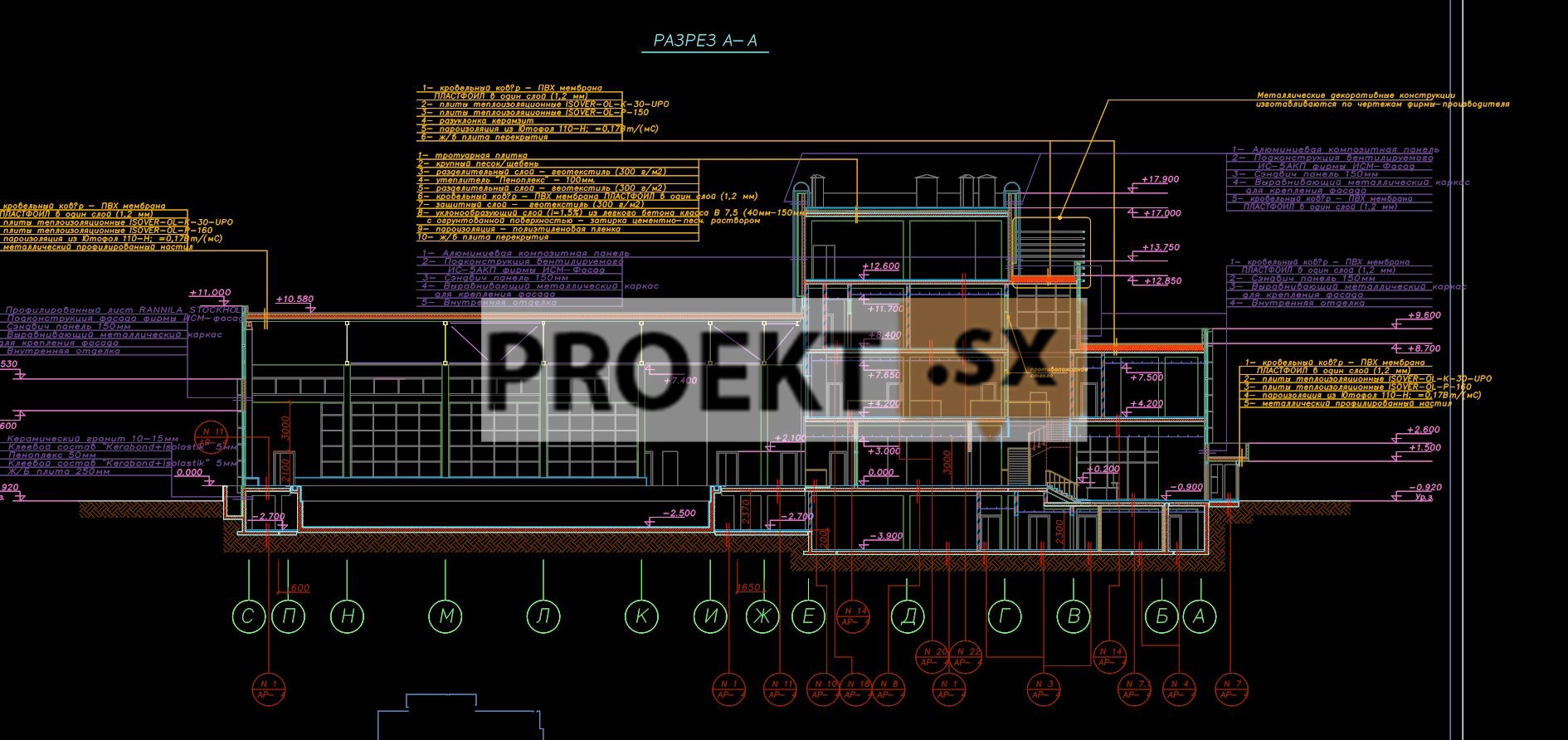

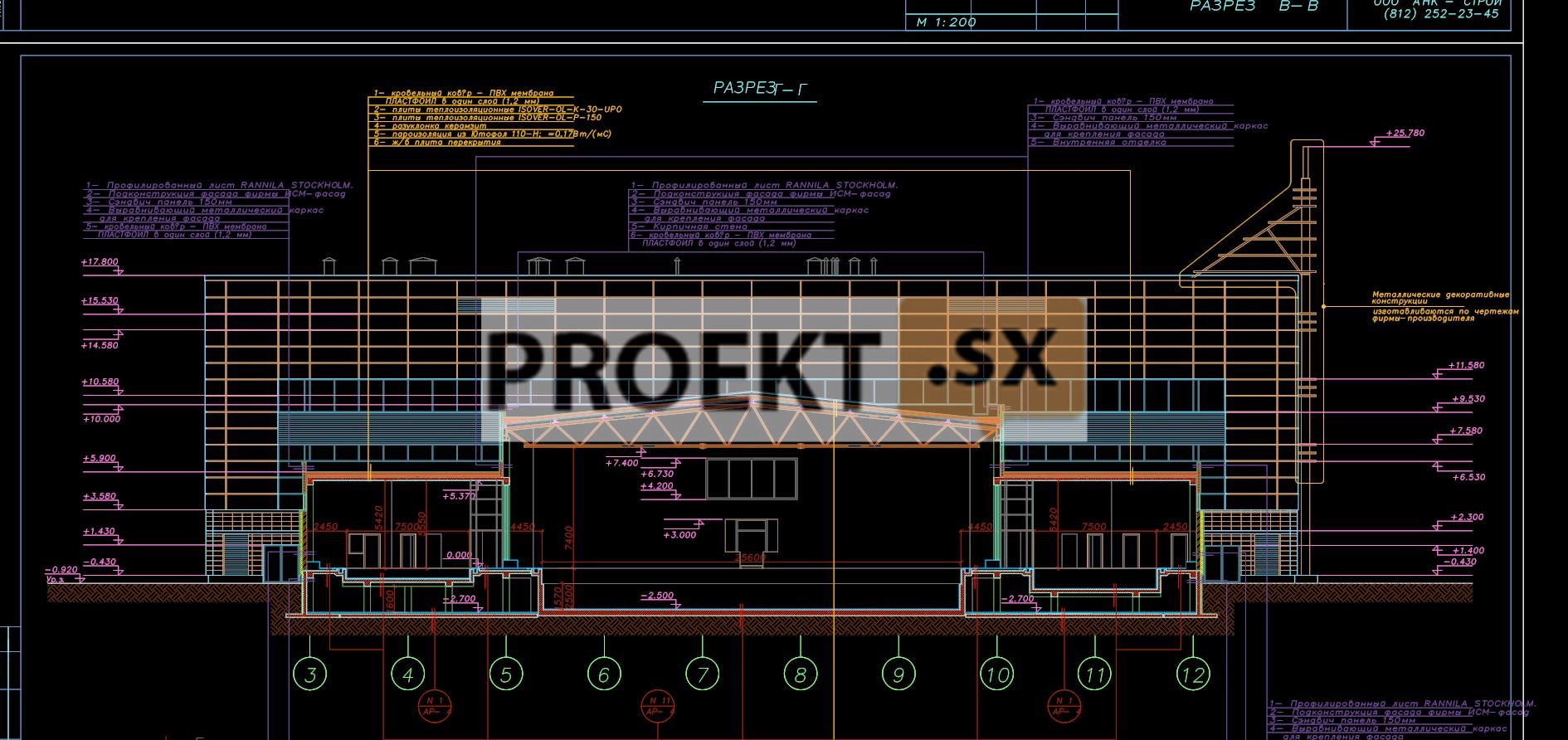

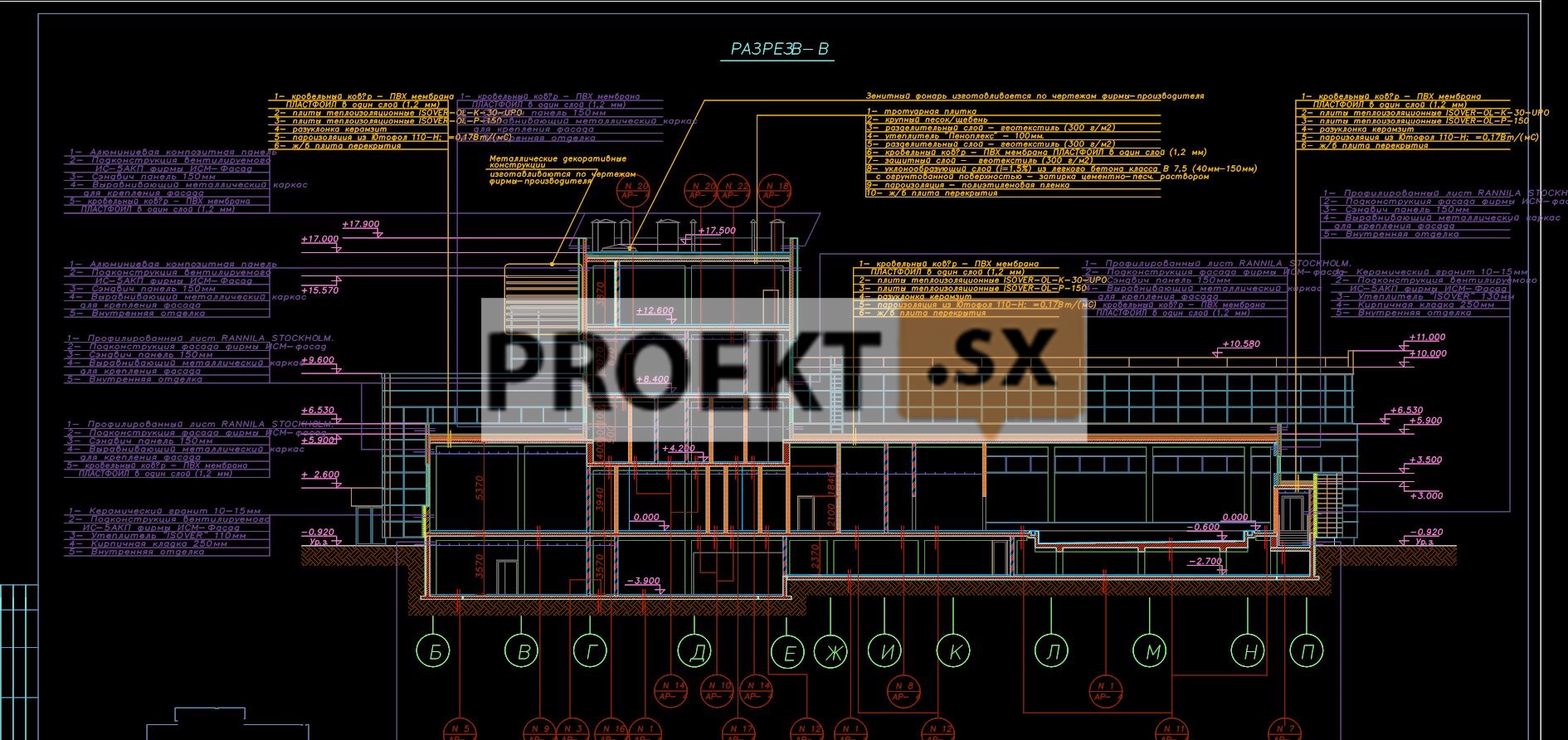

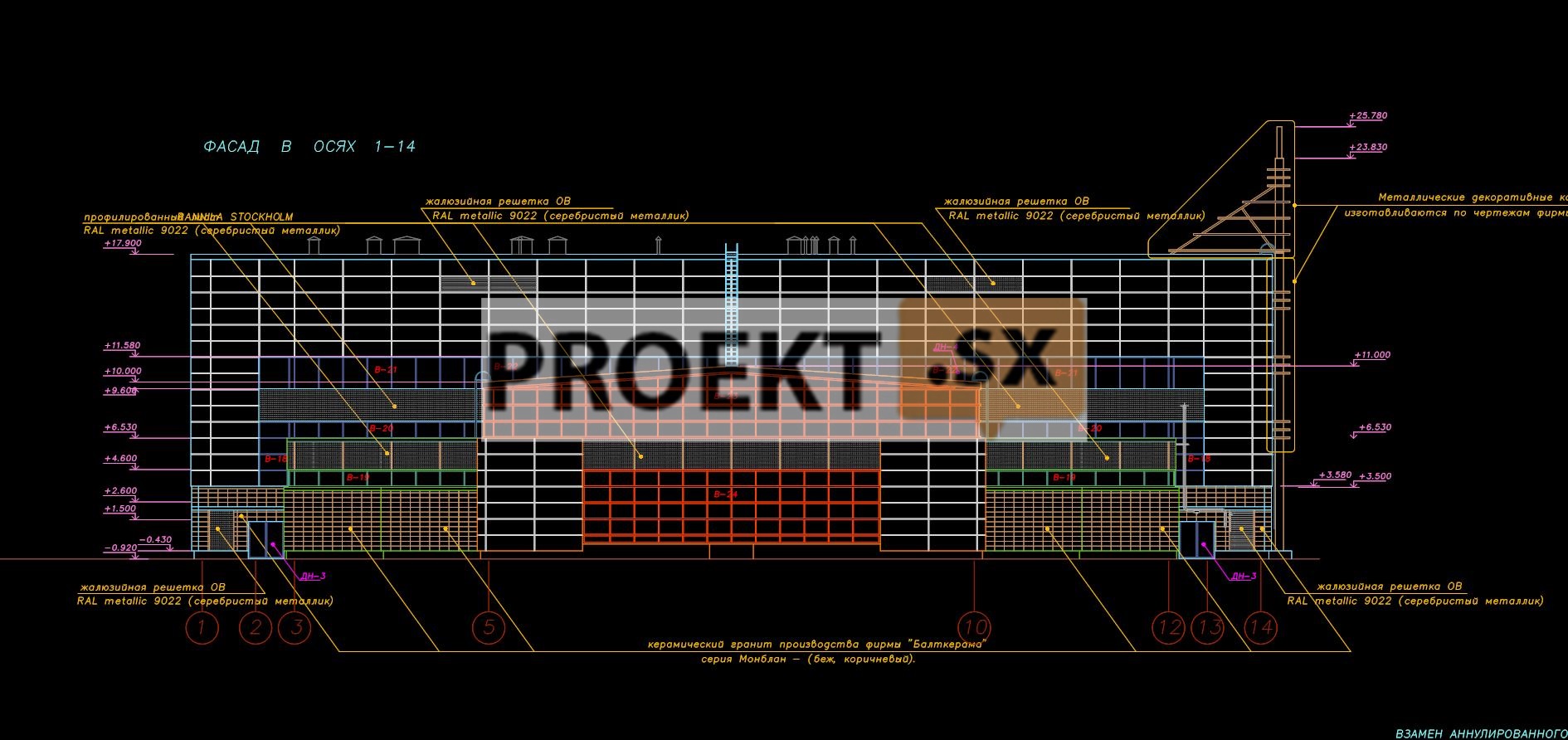

The designed building of the swimming pool without stands for spectators is a separate 1-2-4-storey building with different cover configurations. A building with a basement, a broken rectangular shape in plan with dimensions in the extreme axes 58.20x65.40m. For a relative mark of 0,000, the level of the finished floor of the 1st floor was taken. The maximum height of the vertical plane of the facade from the planning ground level to the top of the parapet is 18.82 m, which does not exceed the maximum height (40.0 m) of buildings located in the depths of the quarter of the TP0-1 zone of this land plot. Functionally and structurally, the building is divided into two blocks. One block includes sports halls with a group of auxiliary and related premises, amenity premises, administrative premises, catering premises and a technical floor. The other block includes three pools. In the basement floor, pool maintenance rooms (water treatment, dosing of chemical reagents), dressing rooms with showers (separately for administration and staff), rest rooms, generator room, inventory, ventilation chamber, prechamber, water metering unit, engineering communications rooms, utility rooms are designed. On the ground floor, a hall with an administrator's desk and a cash desk, a security room, a cloakroom for visitors, a control room, locker rooms with showers (men's, women's and children's), halls with pool bowls, locker rooms for coaches and judges, a gym, a nurse's office, laboratories, a hall preparatory classes, judges' room, loading cafe, technical and auxiliary premises. On the second floor, a hall, administration premises, a cafe for 48 seats, a doctor's office with a waiting room, and bathrooms are designed. On the third floor - administrative offices, bathrooms. On the fourth technical floor - ventilation chambers, prechamber, boiler and machine rooms, main switchboard, technical rooms. Stairwells L1 and H2 were designed for evacuation and communication between floors. The building provides for the installation of passenger elevators with a carrying capacity of 400 kg and two small cargo lifts with a carrying capacity of 100 kg. External walls - from the planning mark of the ground to the mark of 0.000 - monolithic reinforced concrete 250 mm thick with foam insulation and subsequent finishing with porcelain stoneware on an adhesive mortar. External walls from the mark of 0.000 to the mark of plus 3.970m - brick 250mm thick with insulation with mineral wool boards and subsequent finishing with porcelain stoneware according to the "ventilated facade" system. The outer walls above the mark plus 3.970m are stained-glass windows and a system of hinged self-supporting "sandwich" panels finished with facade cassettes. Partitions - brick, aerated concrete blocks, plasterboard (simple and moisture resistant) on a metal frame with mineral wool filling, tongue-and-groove (simple and moisture resistant). Windows and stained-glass windows - aluminum profiles filled with double-glazed windows. Doors - metal-plastic and metal, office and wooden, glazed and deaf, fire-resistant and conventional, custom-made and in accordance with GOSTs. Covering - flat and gable, combined insulated. Roofing - from rolled materials, separate operated areas - with a protective coating of paving slabs. The drain is internal. Exterior finish of the building - ceramic granite slabs, aluminum composite facing panels. Finishing of the premises and floors - in accordance with the purpose of the premises: floors - granite, porcelain stoneware, concrete, ceramic tiles, TZI linoleum, pile-free carpet. The design of the floors in the halls of the pools is provided according to the "warm floors" system; walls - ceramic, polymer or glass tiles, plaster, water-based paint; ceilings - water-based paint; suspended and false ceilings - slatted, aluminum and "Armstrong" type. Measures are provided to ensure the accessibility of the building for the disabled and people with limited mobility: the dimensions of the entrance vestibule are taken to be at least 1.50m deep and at least 2.20m wide; width of corridors - not less than 1.60m; flooring is made of non-slip materials, roll materials are lint-free; elevators are designed in the vestibule area and on the bypass path of the health-improving pool; width of door and open openings - not less than 0.9m.

Structural and space-planning solutions:

The pool building is designed according to the frame structural scheme, divided by an expansion joint into 2 blocks along the length. Columns - from monolithic reinforced concrete, section 400 x 400 mm, with variable pitch (maximum pitch 6,0 x 9,6 m, in the pool area pitch - 30,0 x 3,3 ÷ 6,0 m). Concrete B25, working reinforcement A-III. Ceilings and roofing - from prefabricated reinforced concrete slabs with a maximum span of 9,6 m, 400 mm thick, in the area of \u180b\u450brooms with wet and wet conditions - from monolithic ribbed reinforced concrete slabs 400 mm thick. The cross section of the floor beams (including the slab) is 300 x 300 mm and 25 x XNUMX mm. Concrete BXNUMX. Covering over the pool - steel trusses with a span of 30 m in increments 3,3 ÷ 6,0 m, made of closed bent-welded profiles (upper chord - from □ 180 x 140 x 5, lower chord - from □ 140 x 5, lattice - from □ 100 x 5) on which runs from closed bent-welded profiles and bent channels (step 1,5 and 3 m) and profiled flooring H75. Horizontal stiffness ties at the level of the upper chord of trusses and vertical stiffness ties from the truss plane - from closed bent-welded profiles. Pipe steel C345 and C255. Vertical braces of the frame stiffness - cross and portal - from closed bent-welded profiles. The outer walls of the building are of the “ventilated facade” type, consisting of self-supporting brickwork made of ceramic solid brick 2100 kg / m3, M125, F35 250 mm thick on a mortar M100 and a layer of insulation with a thickness 110, 130 mm with porcelain stoneware slabs (on a galvanized steel frame) with an air gap device. Brickwork - with reinforcement and fastening to reinforced concrete with galvanized steel anchors. The outer walls of the basement are made of monolithic reinforced concrete 250 mm thick. Partitions - from aerated concrete blocks, in rooms with a damp and wet regime - from tongue-and-groove hydrophobized slabs. The bowls of the pools are made of monolithic reinforced concrete. Walls of the big pool - variable thickness from 350 to 200 mm. Walls of small pools - thick 200 mm. Bottom slabs of small pools - 200 mm thick, supported by columns of the sub-basin space through reinforced concrete beams. Beams - section 300 x 450 mm. The spatial rigidity and stability of the building is ensured by the joint work of the frame, vertical braces and floor hard disks. The calculation of load-bearing structures was carried out on a computer using the program "SCAD Office" v.11.1. Stairs - prefabricated reinforced concrete steps (series 1.155.1) on steel stringers. The foundations of the building (including small pools) are piled, the slab of the bottom of the large pool is on a natural foundation. Piles - prefabricated reinforced concrete, driven with a section of 40 x 40 cm, length 9,0 m. Concrete B25, W4, F100. The absolute mark of the pile tip for block A is minus 4,20 m, for block B - minus 3,00 m. The connection of piles and grillage is rigid. The allowable design load on the pile (55 tf) was adopted based on the results of static sounding. Before mass pile driving, the bearing capacity of the piles will be checked by static tests. After driving the piles, control tests of the piles will be carried out. The design load on the piles - 60 tf - was adopted based on the results of static sounding (according to the calculation, the maximum force in the piles is no more than 54 tf). Grillages - columnar piles under the bush, made of monolithic reinforced concrete, 750 mm high. Concrete B25, W4, F100, working reinforcement A-III. The absolute mark of the bottom of the grillage of block "A" is + 4,50 m, the grillage of block "B" is + 5,00 m. The retaining walls of the basement are T-shaped with a wall and slab thickness of 250 mm, made of monolithic reinforced concrete, separated from the grillage by expansion joints. Concrete B25, W4, F100, working reinforcement A-III. The bottom slab of the large pool is made of monolithic reinforced concrete with a thickness of 300 mm. Concrete B40, W8, F100, working reinforcement A-III. Preparation for grillage and pool slab - from a layer of monolithic concrete B12,5, W4, F100 100 mm thick over a layer of sand 300 mm thick (500 mm under the pool slab). The calculation of the foundations is made manually according to the formulas of SNiP. The relative elevation of 0,000 corresponds to the absolute elevation of + 9,250 m (top of the pool). In accordance with the report on engineering and geological surveys, the piles are based on light silty gray loams with gravel, refractory with IL = 0,38, φн = 18°, Е = 130 kg/cm2 and light silty semi-solid loams with IL = 0,19, φn = 20°, E = 150 kg/cm2. The base of the bowl of the large pool is heavy silty semi-solid loam with IL= 0,15, φII= 20°, E = 140 kg/cm2. Bulk soils are replaced by a sand cushion. The maximum groundwater level is near the daylight surface. Groundwater is non-aggressive to concrete of normal permeability. In order to protect the concrete of underground structures, coating waterproofing has been adopted. The expected average settlement of the building is ~1,9 cm. The project documentation provides for monitoring of the construction and surrounding development, located at a distance of 18 m from the nearest building.