Did not you find what you were looking for? Ask us! We have archives of 140 TB. We have all modern reuse projects and renovation projects for Soviet standard buildings. Write to us: info@proekt.sx

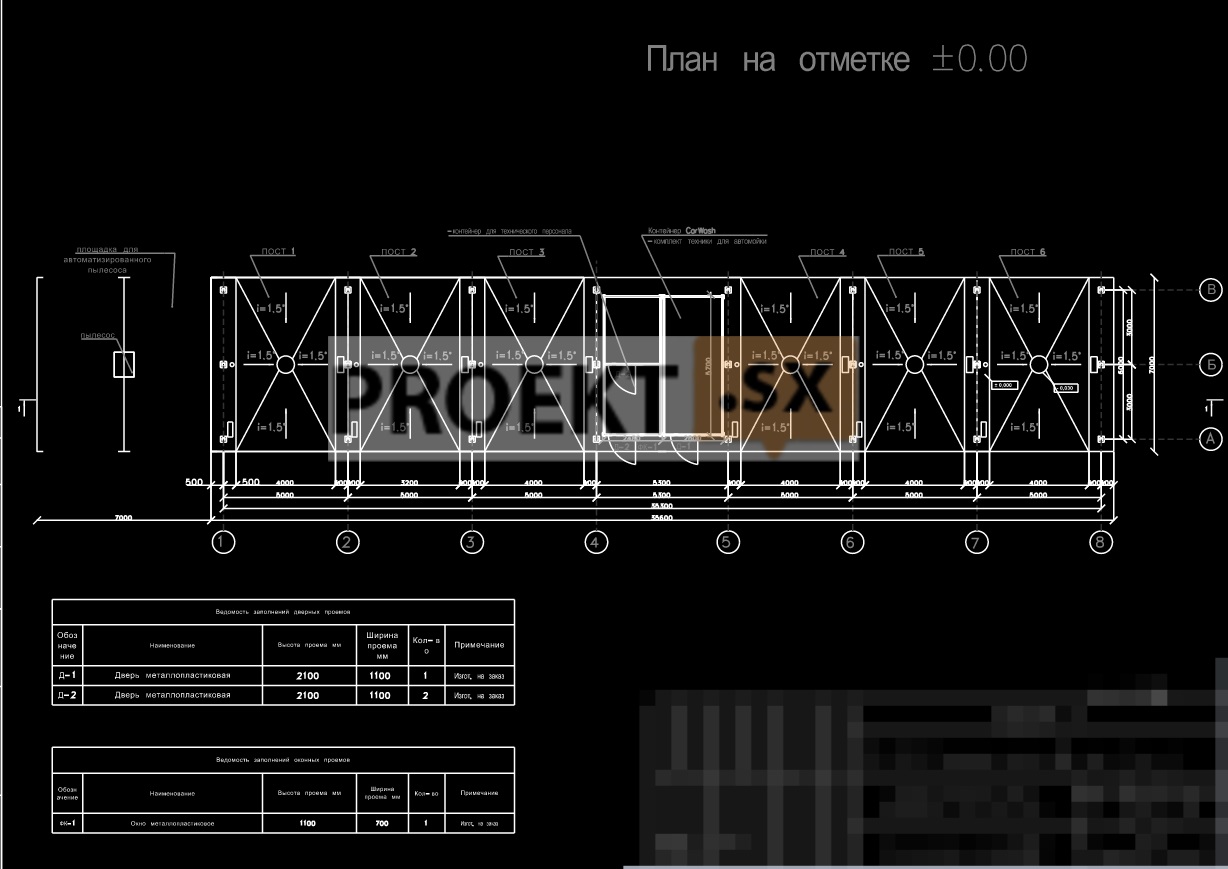

Self-service car wash project for 6 posts

Technical and economic indicators

Building area, m2: 254,1

Driveway area, m2: 49

Sidewalk area, m2: -

Design area, m2: 303,10

Driveway area, m2: 84

Improvement area, m2: 84

Estimated cost of work: 1872 thousand rubles.

Estimated cost of materials and equipment: 2493 thousand rubles.

Total estimated cost: 4365 thousand rubles.

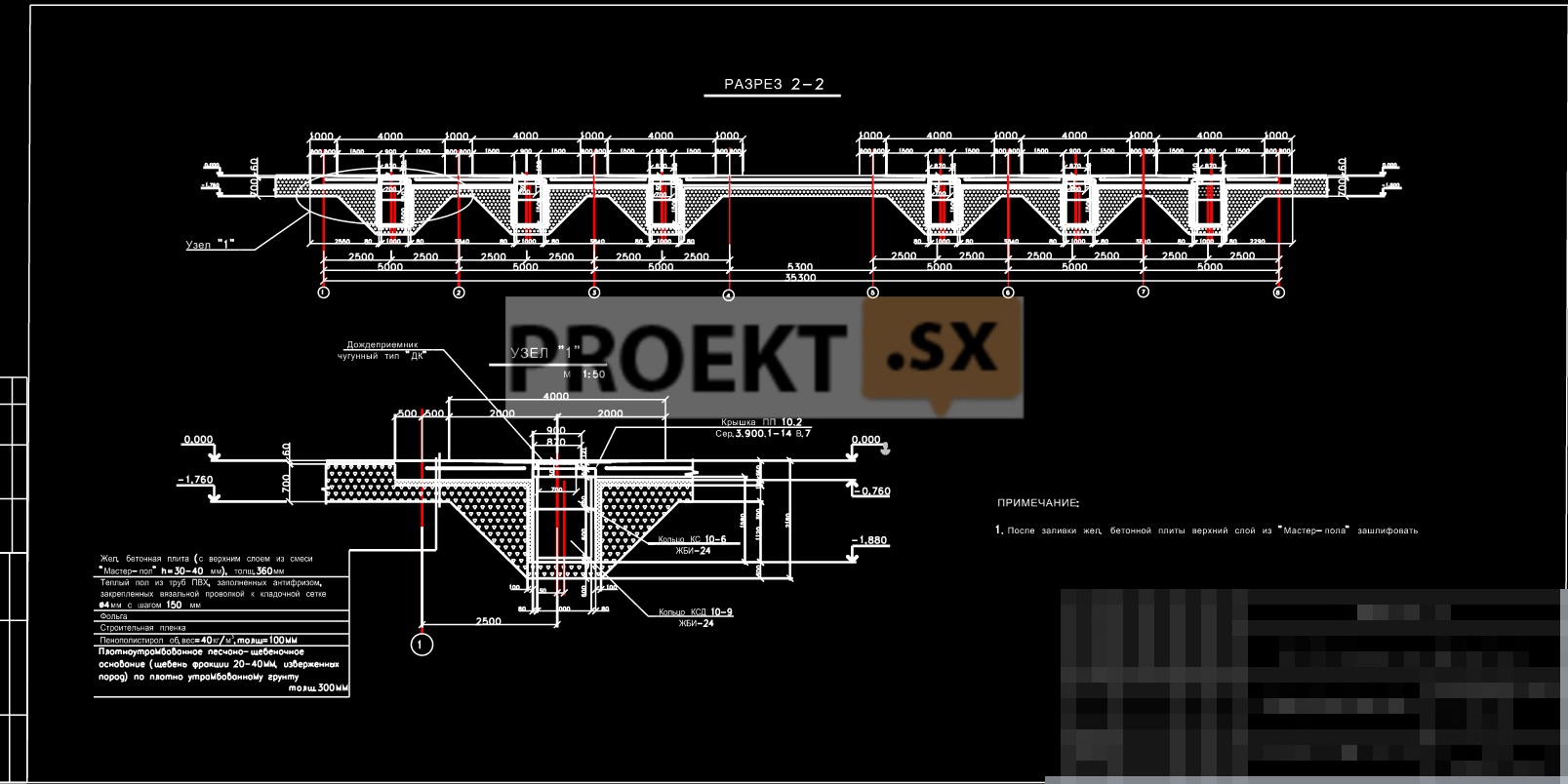

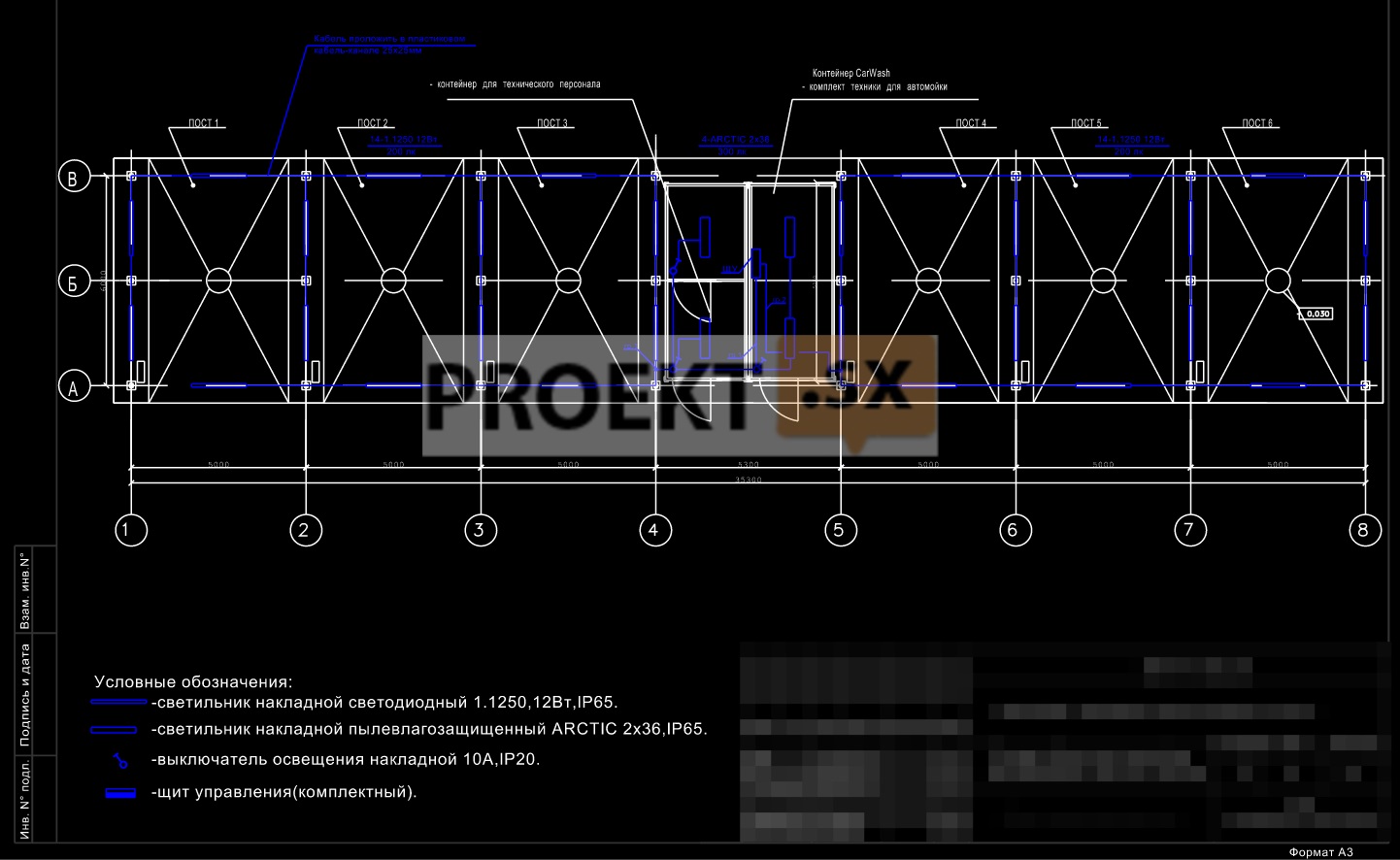

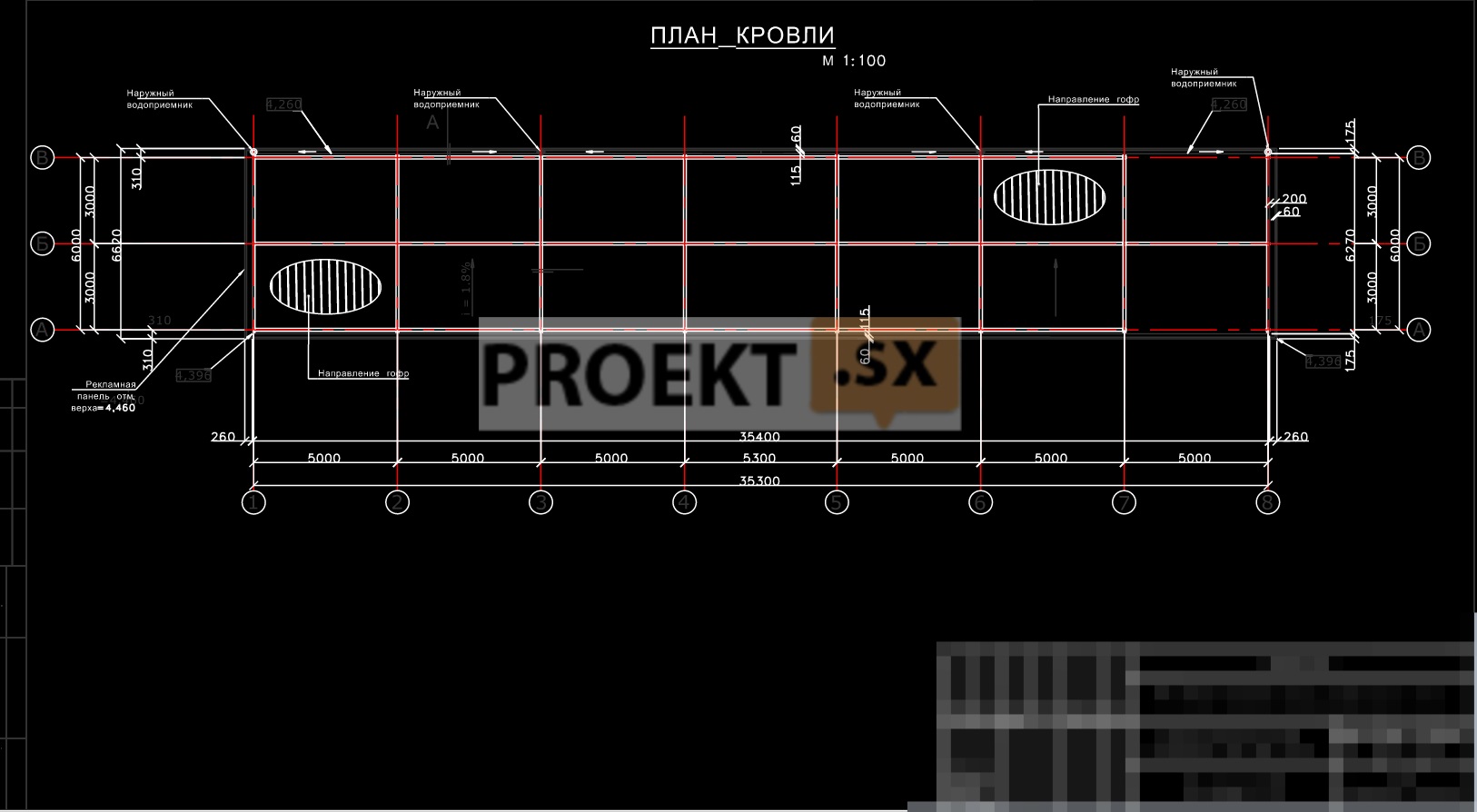

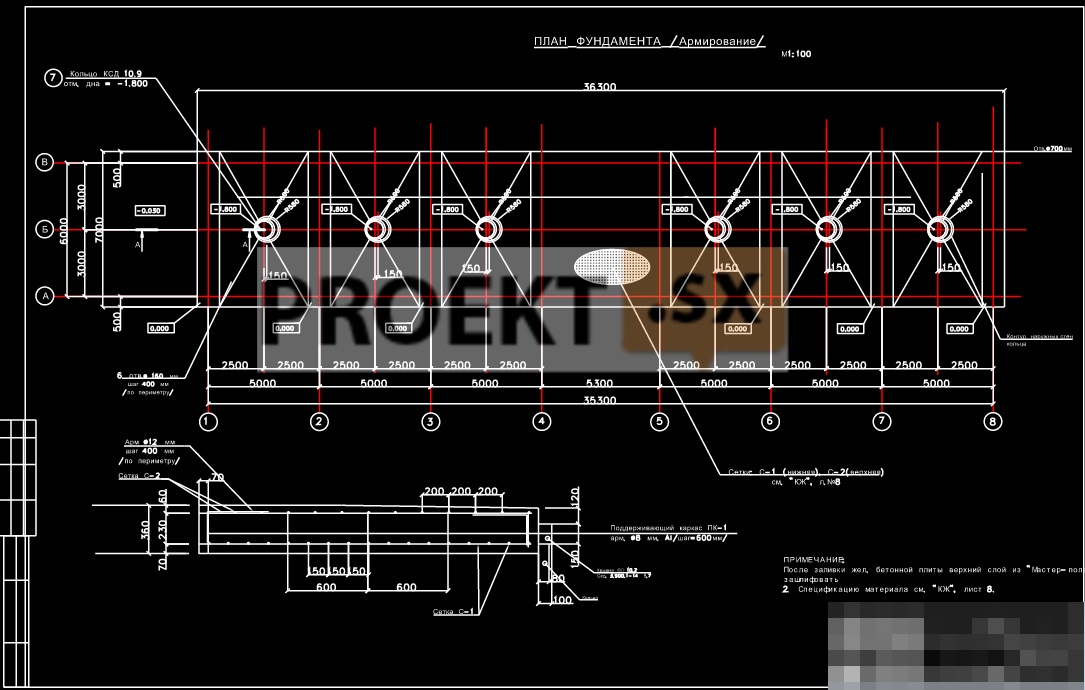

Architectural, constructive solutions. Space-planning solutions

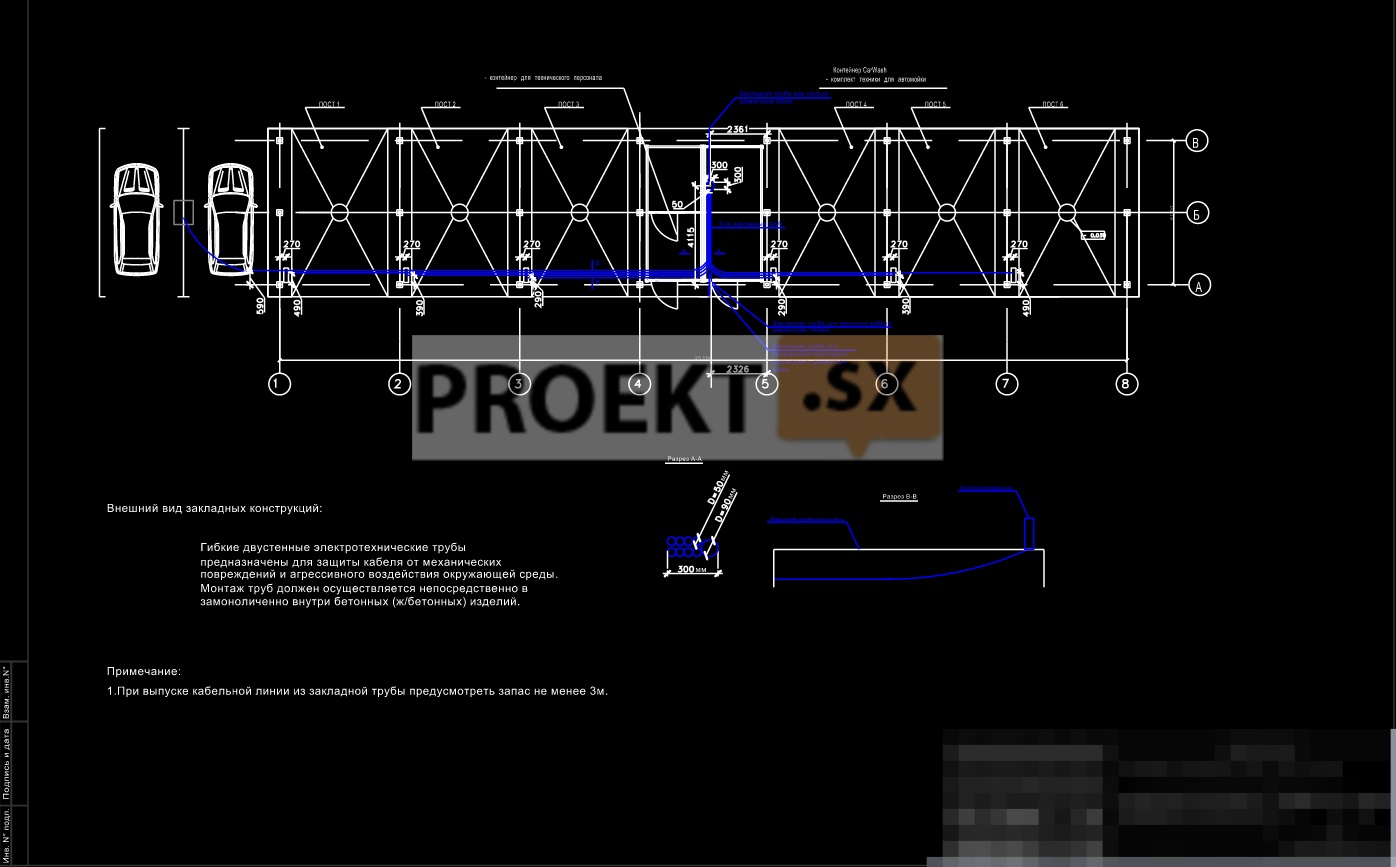

The object of temporary construction is a single-level contactless car wash with axes dimensions of 35.30 by 6.00 m. Roof: flat. The car wash building has a rectangular shape with an elevation of 4.450 m (below the advertising banner). Height in the technical room - 3 m. 0.000 located: 6 stations for washing cars (separated by PVC banners with maintenance instructions) a container with equipment (consists of a complete set of equipment on a single rack with connection of a water treatment station, a washing station and a two-speed heater) a container for technical personnel, 2 parking spaces with a vacuum cleaner . PThe project adopted a monolithic slab foundation made of concrete B 22.5, M 6, P150, arranged on a densely packed sand and gravel base. For a relative mark of ± 0.000, the mark of the top of the iron-bet. slabs Refer to the master plan for reference on the ground. Waterproofing - vertical (all surfaces in contact with the ground - coating with liquid penetron or hot bitumen for 2 times). Backfill the sinuses of the pit with medium-grained sand, followed by trombling with a coefficient. compaction Ku = 0.95 (from natural density). Reinforcement of the foundation slab and slabs is carried out with meshes of individual reinforcing bars 0 12, 16 A-Sh with a step of 150 mm, in both directions. Grids are installed in the upper and lower zones of the foundation slab. Reinforcing bars are combined into a mesh using a knitting wire. The overlap of reinforcing bars should be performed in a run-up with a long overlap of at least 34 0 of the reinforcing bar. The production of formwork, reinforcement and concrete work is carried out in accordance with the requirements of SNiP 3. 03. 01-87. The production of earthwork and concrete work in the winter period is carried out in accordance with the requirements of SNiP 3. 03. 01-87, taking into account the following requirements: exclude freezing of the soil by carrying out work stopovers (one entry is equal to one shift), after which cover the place of work with a layer of insulation (insulating fills or mats). up to air temperature = -10° С, concreting should be done with concrete with anti-frost additives and electric heating should be carried out. Conduct earthworks in accordance with the requirements of TSN 50-302-96. Backfilling should be carried out with compacted sand and poured with water every 300 mm.

Water supply and water disposal

Water supply and replenishment of irretrievable water losses of a typical non-contact car wash is carried out from on-site water supply networks. The connection point is the pipeline for supplying cold water to the DHW system in AITP. At the connection point, a water consumption meter with a pulse output is installed, weld-in ball valves are designed. The laying of water pipes along the AITP is made of galvanized steel pipe; to prevent the formation of condensate, thermal insulation from the K-FLEX ST material is designed from the tie-in point to the exit of the pipes into the ground. Further, through pipelines mounted from pressure polyethylene pipes Isoproflex-Arctic 50/110, located in the soil below the freezing depth, water is supplied to the technological room - the car wash container. Taking into account modern requirements and technologies, the project provides for the recycling water supply of the self-service car wash. Contaminated process water after use enters the receiving trays-wells and then by gravity through a separate outlet through pipelines mounted from pipes of corrugated two-layer Ikaplast Du160 mm, they are fed into the Flotenk-settler-sand trap, where particles of large fractions are deposited. Further, the clarified effluents enter the Flotenk unit, where they undergo complex treatment. The Flotenk block is a tank that includes a gasoline oil separator, an aeration system and a storage tank, made in one housing. The treatment plant uses a method based on the ability of microorganisms to use many organic and some inorganic compounds contained in wastewater as a nutrient. Deep biological treatment allows you to remove a variety of organic compounds, including toxic ones, from wastewater. Oil-petrol oil separator - with a capacity of 6 l / s, coalescent modules are installed in it, with the help of which free, as well as partially mechanically emulsified oil products are separated from wastewater. Another advantage of the modules is that the modules are self-cleaning. When flowing, water creates vibrations, i.e. the modules vibrate, thereby contributing to the ascent of oil particles and the settling of particles of suspended solids. The oil-petrol separator is equipped with a signaling sensor that controls the thickness of the layer of oil that has surfaced. When the limit oil volume is reached, an alarm is activated, allowing the separator to be emptied in time. The modules are serviced by removing them and washing them with a jet of water, followed by installation in their seats, at least once every three years. The removal of the oil film, after the level sensor is triggered, is carried out by pumping out with a cesspool machine, followed by removal to a special landfill. flotation fine filter, filled with hydrophobic sorbent HEC. The sorbent is a composite material based on natural aluminosilicates. It has a number of advantages in comparison with the sorbent widely used for these purposes, based on activated carbon. It allows: to operate treatment facilities without replacing the sorption load for up to 3 years, to ensure a high degree of purification throughout the entire period of operation. Degree of purification: for suspended solids (vv) - up to 20 mg/l; for oil products - up to 0,3 mg/l. After treatment, the treated effluents are discharged by gravity into the existing well of on-site storm sewer networks. If necessary, the treated effluent undergoes additional treatment at the TVT unit located in the technical staff unit (see the VC section). The unit (symbol TVT) is designed for post-treatment of car wash wastewater and further discharge of the leachate (depending on the results of water analyzes) into the sewer or into the return pipeline for supplying water to the car wash. The modules of the TVT installation contain replaceable filter cartridges manufactured by Geyser LLC. At present, only the Geyser company has the technology for mass production of these materials. PGS polymers are fundamentally new materials that combine three filtration methods at once: mechanical, sorption and ion-exchange. None of the existing materials provides cleaning for such a wide range of chemical compounds as PGS polymers. Microglobules have a large internal surface (up to 500 m2/g). The surface of the microglobules itself is covered with active groups, on which the ion exchange takes place. The removed ions directly interact with the chemically active surface of the polymer, bypassing the stage of diffusion into the depth of the granule, which is traditional for ion-exchange resins. As a result, the volumetric filtration rate of PGS polymers is 10-20 times higher than that of conventional granular ion-exchange resins. This is an important advantage of PGS polymers. Removal of mechanical impurities mainly takes place in the surface layers of the polymer. The pore size can be any in the range: 0.01-3.5 µm. By changing the synthesis conditions, it is possible to obtain the desired material porosity with a spread of no more than 10%. At present, Geyser has studied and developed technologies for the production of more than 30 modifications of PGS polymers. Materials with both cation-exchange and anion-exchange properties have been obtained. For the complex removal of harmful impurities from water, the best performance has a polymer based on resorcinol - "ARAGON". Mechanical filtration of all particles larger than the dimensions of the outer pores of the material occurs on the surface. The filtration channel has a complex sinuous shape with gradient porosity. This makes it impossible to discharge filtered harmful impurities into purified water, which often happens with pressure surges. The number of free channels in the material gradually decreases, reducing the pressure of purified water. The filter element based on the material "ARAGON" can be used repeatedly. With the beginning of filtration, the EMC for supplying raw water to the HWT opens, the servomotor opens the ball valve on the filtrate supply line, and water from the mixing tank is supplied by means of a pump to the middle and upper dirty water collectors, interconnected by a jumper with an air vent. From the collectors, water under constant pressure (to be specified during commissioning tests) is supplied through connecting pipelines to the cavities of the filtration cartridge modules. In the modules, water passes "from outside to inside" of replaceable cartridges. The entire volume of dirty water supplied to the cartridges is filtered through them. All contaminants are collected on the surface or in the volume of the cartridges, forming a layer of deposits. Over time, the thickness of this layer increases, and as a result, the filtrate flow decreases. After a significant increase in resistance and, as a consequence, an increase in the pressure drop at the inlet and outlet of the HTT installation, the filtration process decreases or stops. The performance and resource of the cartridges depend on the content of contaminants in the water. Clean water (filtrate) through the internal cavity of the cartridges enters the lower manifold, from where it is fed through a rotameter (water meter) and a ball valve with an electric drive under the pressure of the installation pumps into the pressure absorber well and then by gravity through the control well into the existing well or to the car wash equipment for re-use. use. The design also provides for a flush water circulation pipeline that supplies purified process water to the car wash equipment in a constant circulation cycle, which prevents stagnation and icing at sub-zero temperatures. All reinforced concrete structures and parts are subject to waterproofing. Before the start of earthworks, it is necessary to call representatives of the operating organizations of underground engineering networks and structures to clarify the locations of networks on the ground. The project provides for water supply to the self-service car wash from on-site water supply networks with the equipment of a water consumption metering unit in the AITP building. Stationary self-service car wash is a fully automated, publicly available equipment, supplied in a single container unit and used for washing cars. The process of washing and dosing of detergents and preservation, water heating, payment calculation and implementation of the programs selected using the buttons is controlled by an industrial computer. The main unit in the equipment is a high-pressure pump that creates a working water pressure of 30 to 120 bar. The pump is driven by a three-phase voltage electric motor. Water with detergents is supplied under high pressure through a high-pressure hose system from the car wash to the outside and through a spear or brush to the surface of the car. Car washing is carried out quickly and efficiently, because. a high-pressure fitting at the end of the spike forms a jet of water in the form of a spatula. Washing efficiency is enhanced by a low-pressure stainless steel boiler for hot water. The water used for washing is improved by softening and purifying in the water recycling process. Water is improved by cleaning it from mechanical impurities and minerals. Thanks to this, the effectiveness of the action of chemicals increases, and the surface of the washed car after drying does not leave stains and smudges. Chemicals used in washing are dosed under computer control and using dosing pumps or injectors, which guarantees their economical consumption and gives the expected washing effect. The use of products recommended by the company guarantees high quality of services and accurate operation of the equipment. The equipment is equipped with an anti-freeze system. It works on the principle of forced water circulation. When the ambient temperature drops below 3ºC, a thermostat placed outside the sink will turn on the anti-freeze system, which prevents the water inside the piping system from freezing. In the premises of the block of technical personnel, the project provides for the placement of an additional wastewater treatment plant TWT Geyser LLC, which operates in conjunction with external treatment facilities. The removal of technological waste from the washing equipment is provided for by gravity pipelines, mounted from HDPE sewer pipes laid in the thickness of the floor and further to the OS. After treatment, the treated effluents are discharged by gravity into the existing well of on-site storm sewer networks.

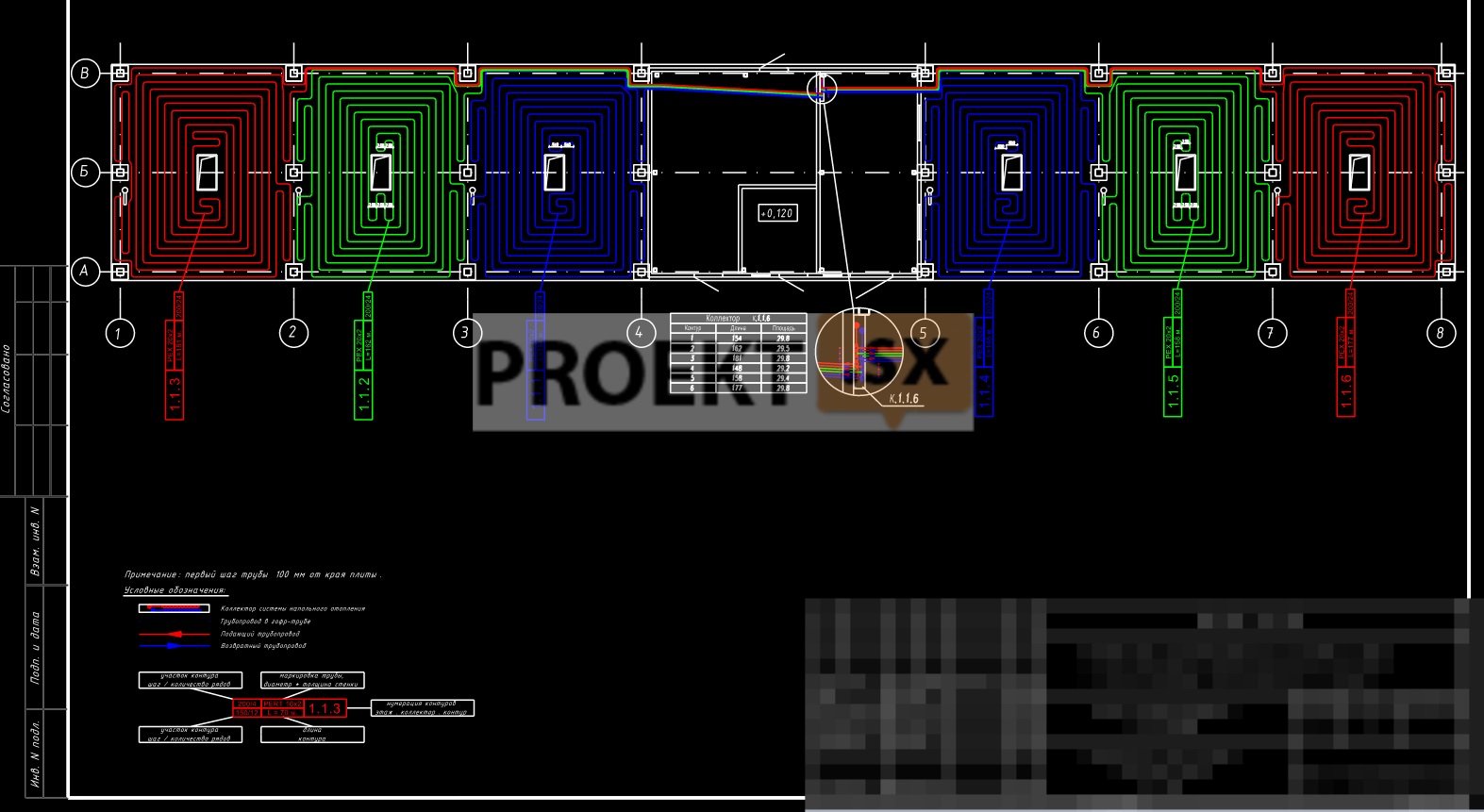

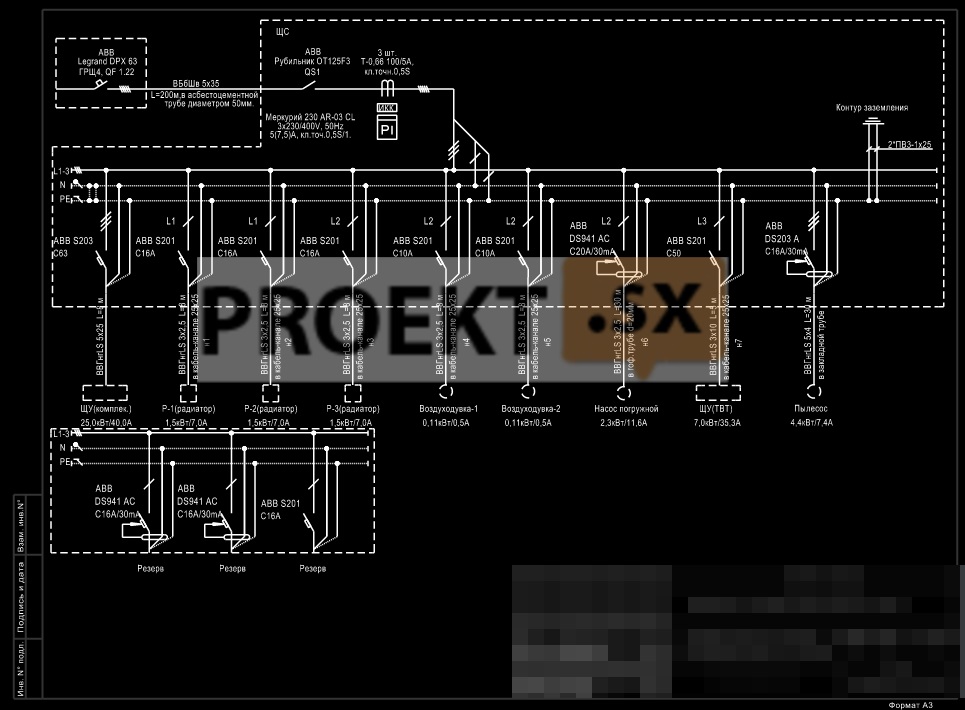

Heating, ventilation and air conditioning

The project provides for the heat supply of the sink from a boiler unit located in the technical compartment of the sink (supplied with a block of heating equipment in a technological container). The coolant is antifreeze. The heating system is combined. The room of the technical module is heated by an electric heater with a power of 1,5 kW, which maintains the internal temperature in the room within +5ºС. The room for technical personnel is heated by two electric heaters with a total power of 3 kW, maintaining the internal temperature in the room within +18ºС. An underfloor heating system has been designed in the washing compartments, which provides a comfortable car wash, preventing the possibility of freezing and icing. Air is released from the heating system at the highest points of the system (on the underfloor heating collector) using automatic air vents. Pipelines of the heating system are laid with a slope of at least 0,002. The ventilation of the premises of the technical module and personnel is natural. The premises are equipped with ventilation openings equipped with adjustable ventilation grilles. All work on the manufacture and installation of heating systems must be carried out in accordance with the requirements of SNiP 3.05.01-85. Design parameters of outside air are accepted in accordance with Appendix 8 of SNiP 2.04.05-91* for parameters "A": Parameters "A". Warm period of the year: outdoor temperature tn = 20,6оC; specific enthalpy J= 48,1 kJ/kg. Parameters "B". Cold period of the year: outdoor temperature tn = - 26C; specific enthalpy J = - 25,3 kJ/kg. The specified parameters are provided in accordance with the requirements of SNiP 2.08.02-89*, SNiP 2.04.05-91 with a normally operating heating system and proper operation of the equipment.